KanbanBOX for handling

With the Milk Run, internal logistics becomes an automatic mechanism that aims to educe stocks and achieve maximum efficiency

The origin of the Milk Run is inspired by the old door-to-door milk supply method. A simple and functional method for the supplier, empty bottle for full, capable of satisfying, in a clear and punctual way, a regular and constant need of the customer, thereby optimising resources.

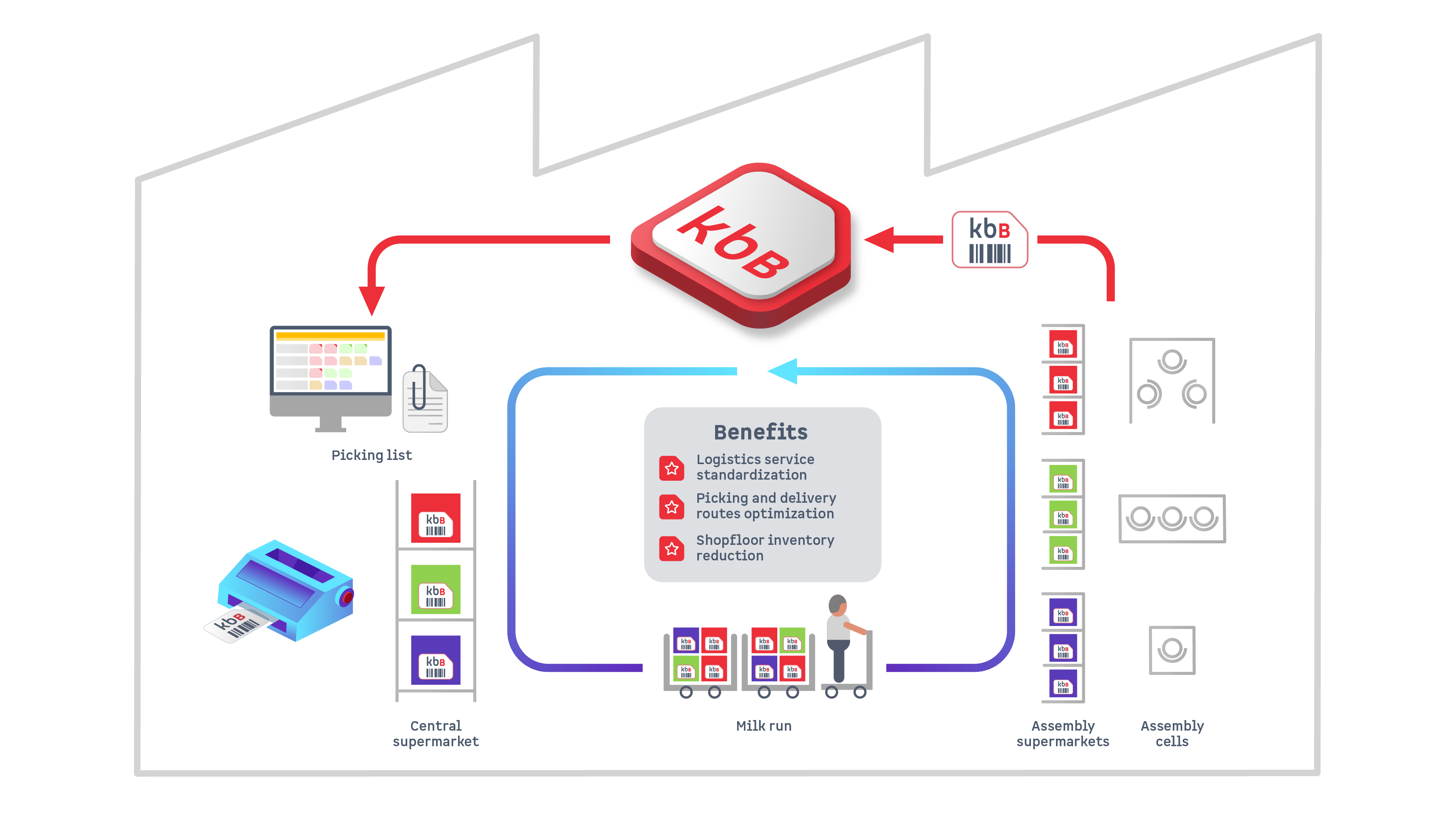

When many workstations need to be stocked, a standardised system is needed to guide replenishment workers. KanbanBOX collects the list of all components to be replenished by reading bar codes and optimises picking and delivery routes (Milk Run).

How the Milk Run

logistics function works

By reading the barcodes in each production station, KanbanBOX collects a list of all the components to be replenished and proposes the shortest path to picking.

- standardise logistics and picking

- create pull pick lists

- standardise internal logistics

- optimise picking and delivery routes

- reduce departmental inventories.

the benefits of coordinated

transport with a Milk run logic

With KanbanBOX’s Milk Run management, internal logistics becomes an automatic mechanism that aims to reduce stocks and maximise efficiency. The benefits of the Milk Run are:

- simplified logistics management

- reduction of resources dedicated to transport planning

- optimisation of supply flows

- reduction of stocks and inventory value

- reduction of transport and logistics costs

- improvement of the load factor of the vehicles (small lots are better organised in terms of space)

- reduction of the delivery cycle

- increased production flexibility.

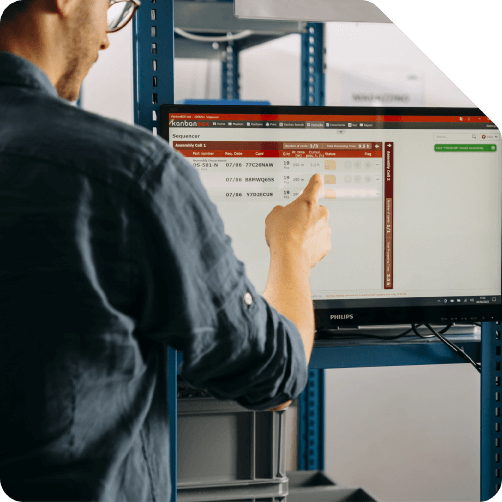

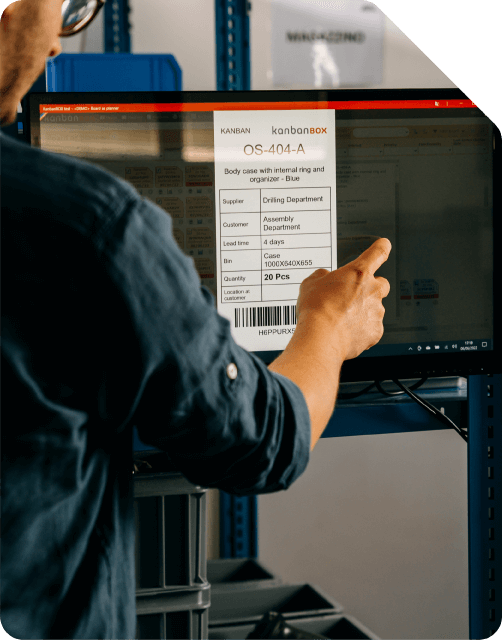

See KanbanBOX in action

The platform for the management of internal logistics with electronic kanbans

Case studies

Anodica Trevigiana

From the automation of the kanban system to the creation of a digital Supply Chain: Anodica's design and Italian products redesigned from a Lean perspective.

Ideagroup

A leading company in the production of bathroom furniture, it switches to electronic kanban by introducing KanbanBOX, with excellent results in the management of variable stocks.

Aptiv

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector.

Cadel – MCZ Group

With the extension of KanbanBOX to the Supply Chain, the stock of class A components and the number of line stops are reduced: the lean management of over 2,500 kanban ties.

References

Some of our clients