How to Optimize Kanban Maintenance and Sizing

By Guido Bonuzzi

Anyone who has implemented a manual kanban system knows it works: it improves material management and makes workflows more visual and streamlined. However, as time goes on and the system is expanded to new lines and items, a major obstacle often arises that slows everything down: maintaining the system and recalculating its sizing.

When the issue isn’t the method, but the time required to keep it efficient

A kanban system needs to be kept up to date in order to function properly. Consumption data must be reviewed periodically, sizing parameters need to be updated, and paper cards must be modified. This maintenance work can become surprisingly time-consuming:

- When consumption rates or lead times change, you need to recalculate how many cards are needed for each item. The more unstable the demand, the more frequently you must revise your kanban sizing.

- If you add or remove a card, all existing cards must be updated to reflect the new total count. That’s because each card must show “Card 1 of X”, “Card 2 of X”, etc., meaning every time the value of “X” changes, the entire set of cards must be updated.

- Every change requires printing, cutting, laminating, and manually replacing cards.

These are non-value-added activities, yet they’re essential to keep the system running. If neglected, they compromise the reliability of the kanban system.

The most common tool used for kanban maintenance: Excel

One of the most commonly used solutions is Excel spreadsheets, where formulas are created to calculate the correct number of kanban cards based on consumption, coverage time, and units per kanban. With a well-set Excel file (or similar spreadsheet tool), the Lean Manager can:

- Simulate changes in consumption

- Determine whether it’s time to update parameters

- Track the history of changes

But there’s a catch: everything depends on manually inputting data. When the data isn’t updated regularly, simulations lose their accuracy. It’s also necessary to manually verify whether actual consumption differs from the baseline and decide whether to add or remove cards.

So, Excel is a good first step, but it doesn’t solve the maintenance issue, it just makes it more organized.

KanbanBOX: the e-kanban software that simplifies maintenance

For companies that truly want to optimize kanban management, the most effective solution is to automate the maintenance process. This is where KanbanBOX comes in: a software solution for implementing electronic kanban. [Discover what is electronic kanban in this free guide]

Among its list of features and advantages, KanbanBOX optimizes kanban maintenance and sizing by tackling two key areas: automatic calculation of ideal sizing and simplified kanban card management.

Automatic calculation of sizing parameters

KanbanBOX helps companies with kanban maintenance through the automatic calculation of kanban sizing parameters:

- It tracks all data related to kanban cards, including sizing data, item management policies (e.g., signal kanban, double-bin), pieces per kanban, and consumption frequency.

- Based on these parameters, KanbanBOX automatically calculates the ideal kanban sizing for each item and suggests when to add or remove a card.

Note: whether or not to follow the software’s suggestion is up to the Lean Manager, as there may be constraints like minimum order quantities or warehouse space availability.

Simplified kanban card management

With KanbanBOX, there’s no need to reuse the same physical kanban cards, avoiding the hassle of resetting templates, printing new cards, laminating, and manually replacing them whenever the total number of cards changes.

Here’s how KanbanBOX simplifies it:

- It uses a disposable card system: each card has a unique ID. When a kanban is consumed, the card is discarded and replaced with a newly generated card that carries a new unique ID, to be applied to the replenished material.

- When the number of cards for an item increases, the software automatically generates the new card template, ready to be printed with a single click.

- When the number of cards decreases, after a kanban is consumed, no new card is generated, thus reducing the total card count for that item.

Additionally, KanbanBOX enables users to:

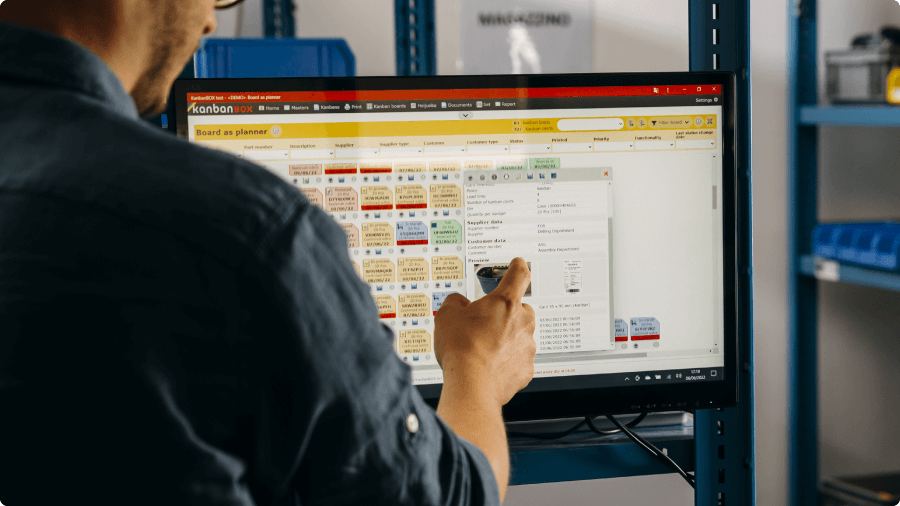

- Get a complete overview of the card status: via the “Board” section of the software, which shows all cards for each item, the user can check how many cards exist and whether they’re available, need to be replenished, are in process, etc.

- Automatically generate new cards and their print files, requiring no manual effort beyond clicking the “Print” icon.

From a managed system to an automated system

With KanbanBOX, kanban maintenance and sizing shift from being a time-consuming but necessary task to a fast, data-driven activity. All this without burdening operational teams or Lean Managers. Time once spent updating cards and monitoring spreadsheets can now be invested in improving processes.

How much can your kanban system improve with electronic kanban?

Read the case study about El.Co., an industrial automation company that transitioned to e-kanban precisely because kanban maintenance had become unsustainable. You can read the case study on our website or on Planet Lean, the go-to publication for Lean professionals worldwide.