KanbanBOX for Supply Chain

Management of supply and distribution flow

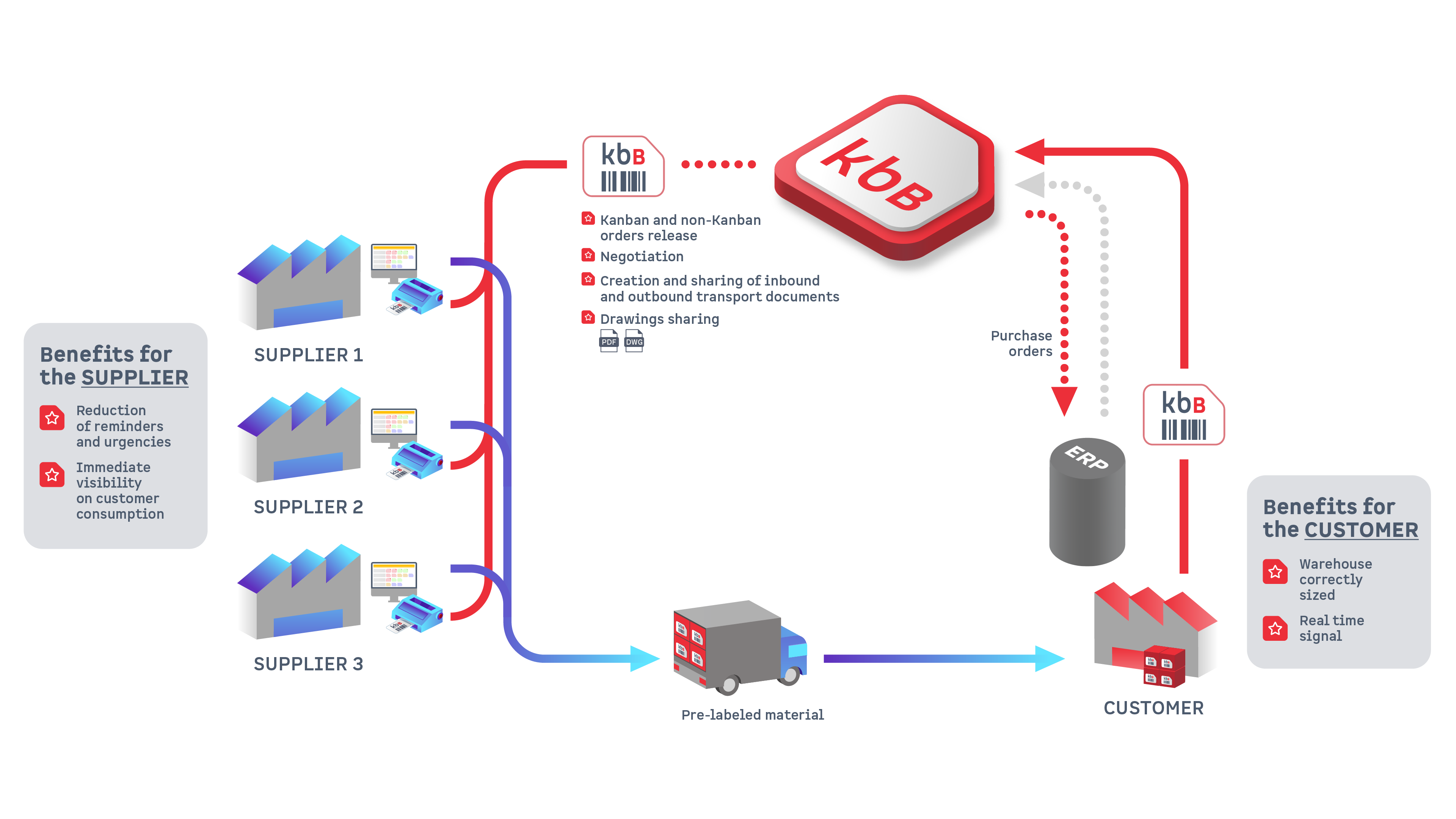

KanbanBOX is the Supply Chain Management solution for managing a manufacturing company’s supply chain and procurement processes. It is a Cloud solution, scalable and integrable with any company ERP that simplifies the communication and procurement process along the supply chain and between the different production plants, adding value to the entire system.

The kanban for managing sales and procurement along the Supply Chain

Companies capable of collaborating efficiently along the Value chain achieve a drastic reduction in costs and stocks and an improvement in terms of productivity, speed and levels of service to end customers.

Companies capable of collaborating efficiently along the Value chain achieve a drastic reduction in costs and stocks and an improvement in terms of productivity, speed and levels of service to end customers.

KanbanBOX activates Supply Chain Collaboration: through a shared portal between sales, production, external branches and suppliers, corporate communication becomes fluid, immediate and interactive.

The portal provides facilitated access to information, allowing you to manage negotiations and the complexity of order processes through electronic kanbans (e-kanban) for procurement, distribution and Synchro orders (closed orders for purchase or order, work orders, Junjo orders).

The pluses of the Supply Chain suite

- Easy connection and collaboration with customers and suppliers

- Scalability to connect with all your customers and suppliers without a numerical ceiling

- Integration with any ERP

- Sharing of information between all actors in the supply chain

- Ability to manage the negotiations

KanbanBOX for procurement

When a company has to purchase many components from its suppliers, it is important to use a tool that allows you to reduce inventory and order management costs without ever having any stock-outs. KanbanBOX allows to simplify and automate the exchange of information with suppliers and to keep kanban sizing always in line with market demand.

- With KanbanBOX, it is sufficient to read the barcode on the kanban card to report consumption to the supplier in real time and that the kanban must be replenished by the agreed date.

- Any supplier can check the status of the kanbans from the virtual whiteboard and print the cards to be replenished. Also, kanbans and closed orders can be managed at the same time.

- The results are visibility on processes, synchronization and sharing of information in real time, the ability to manage any type of order (closed or kanban order), documents and workflows, exchanging data with the company ERP thanks to integration with any management software.

Reduce stocks and order management costs without ever having any stock-outs with KanbanBOX!

Kanban Distribution

Simplify the management of the distribution channel.

Quickly implement the kanban system by automating procurement between company offices, branches, warehouses and production centres, optimising stock and reorder times.

Find out moreClosed purchasing orders

Simplify the management of the distribution channel.

Automate the management of closed purchase orders (Purchase Order) to suppliers by creating a procurement process capable of eliminating waste and low value activities.

Find out moreOn-line negotiations

Simplify the procurement process.

Reduce problems by setting up a clear and visible contractual flow, with a series of automatic procedures that eliminate inefficiencies.

Find out moreReferences

Case studies

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants and integrated KanbanBOX with SAP

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, and then integrated it with its own ERP, with the Oracle Sequencer and with the suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector