Integrate KanbanBOX with Microsoft Power BI

To identify data taken by KanbanBOX in a detailed way and extract dynamic statistics

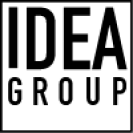

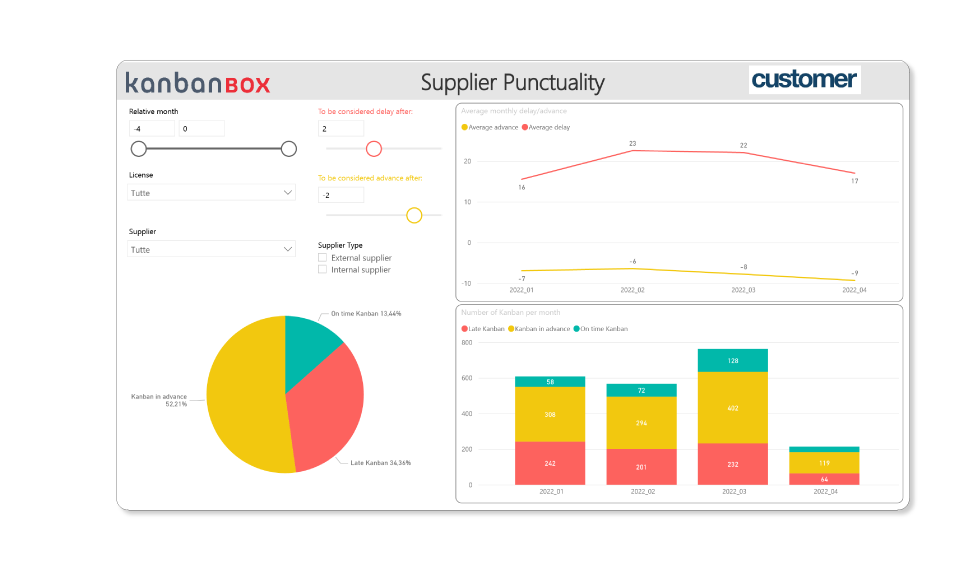

Knowing how to collect data is not enough. The added value lies in knowing how to read it, seeking only that information that is really useful for decision-making processes. KanbanBOX exploits the potential of Power BI, the Business Intelligence software developed by Microsoft, to integrate its own statistics with new, more complex and dynamic statistics. Able to analyse the data detected by KanbanBOX in more depth.

Why integrate Power BI

KanbanBOX is not a data analysis software. That’s why it uses the power of Microsoft Power BI to integrate its statistics with new, more complex and dynamic statistics. Able to analyse the data collected by KanbanBOX in a more detailed and aggregated way!

By automatically extracting layered data, Power BI provides aggregate and dynamic statistics, which can be filtered as needed. With Power BI you can:

- Analyse the data collected by KanbanBOX in an aggregate manner, with objectives not necessarily linked to kanban management;

- For multi-plants, consolidate data from multiple licenses, even with different currencies;

- Gain visibility into the benefits of the Kanban method across the enterprise.

Power BI automatically extracts stratified data, providing aggregate and dynamic statistics, which can be filtered as needed.

The integration packages

Free and easy to use, it provides aggregated data in an advanced stock analysis and in detail on average daily stocks.

Ready and more in-depth, it provides Delivery Analysis, Vendor Rating, Managed Code Analysis, Stock Out Analysis, Workload Analysis, Maintenance Analysis.

In addition to the reports of the PRO version, it provides on-demand customisations such as Graphic review and modification of existing statistics, Development of new statistics, Translation into other languages and Integration with the company ERP.

Case studies

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants and integrated KanbanBOX with SAP

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, and then integrated it with its own ERP, with the Oracle Sequencer and with the suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector

References