KanbanBOX for production plants

The management and control of the production process

Controlling the production cycle is a highly strategic activity for a competitive manufacturing company. For efficient production, capable of facing the instability of demand and quickly satisfying market demands, it is essential not only to plan, but also to balance production by acting on volumes.

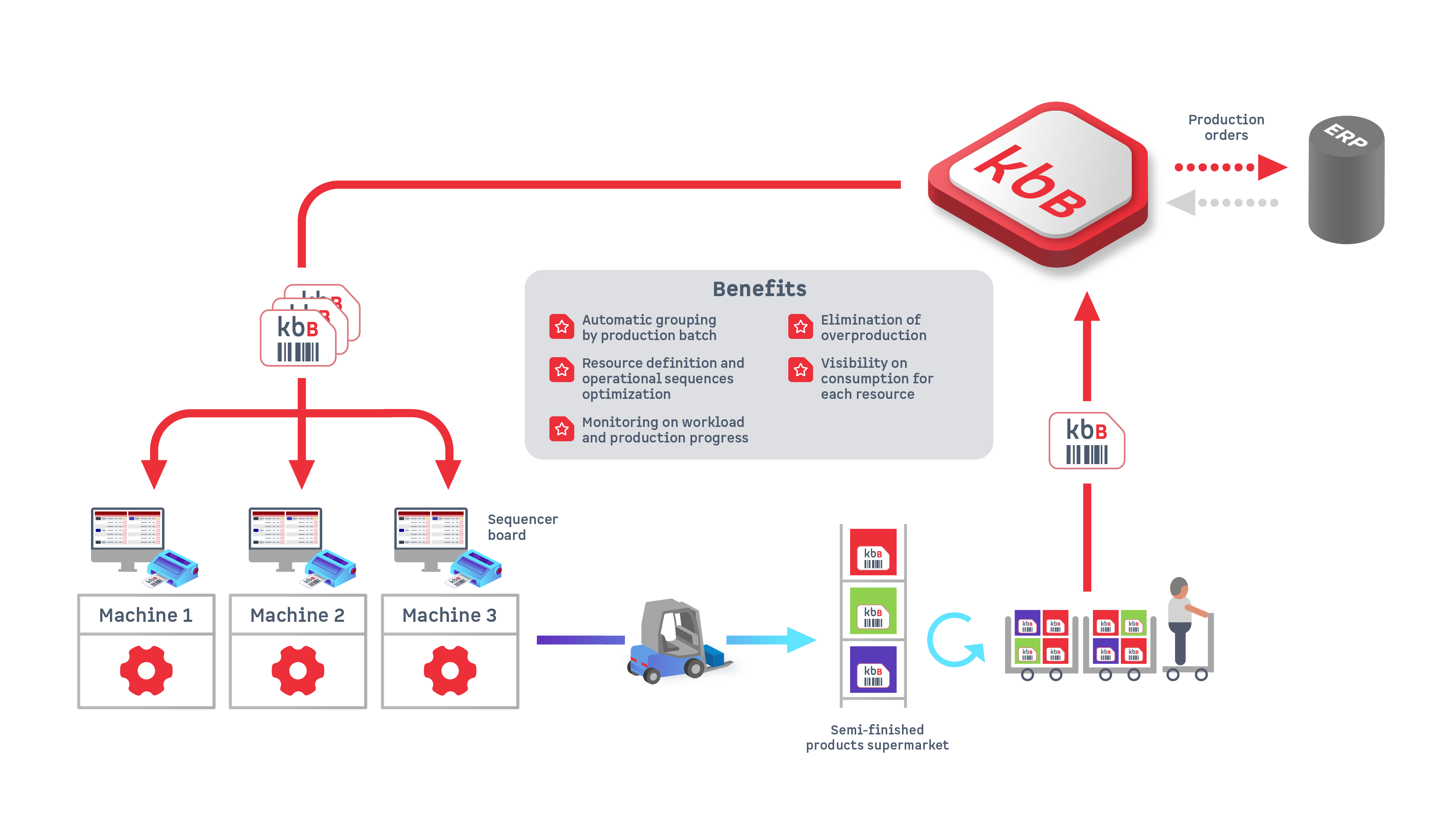

KanbanBOX for production, logistics, sequencing and production levelling (Heijunka and Sequencer), allows you to plan production so that it is always in line with customer requests, automate internal logistics and balance the work load inside the production cell. For the supply chain.

KanbanBOX for kanban manufacturing

For a manufacturing company, production planning is a strategic activity because it allows the company to always be ready to satisfy customer needs.

With KanbanBOX you can:

- Manage the production of materials using a kanban along with other production orders

- Obtaine visibility on workloads and order completion progress.

Furthermore, KanbanBOX will continuously propose the ideal sizing of your kanbans so as to have the lowest possible stocks without risking stock-outs.

Kanban for planning and levelling production

For a manufacturing company without waste, efficient and capable of quickly satisfying market demands, it is essential not only to plan, but also to balance production.

Given the instability of demand, it is difficult to generate reliable forecasts, while levelling production requires acting on production volumes: KanbanBOX allows you to know the workload and the progress of orders, planning production so that it is always in line with customer demands and allocating inventory to address forecast uncertainty.

- By acting on production levelling (Heijunka), which balances the workload inside the production cell by minimising supply fluctuations, production is aligned with takt time.

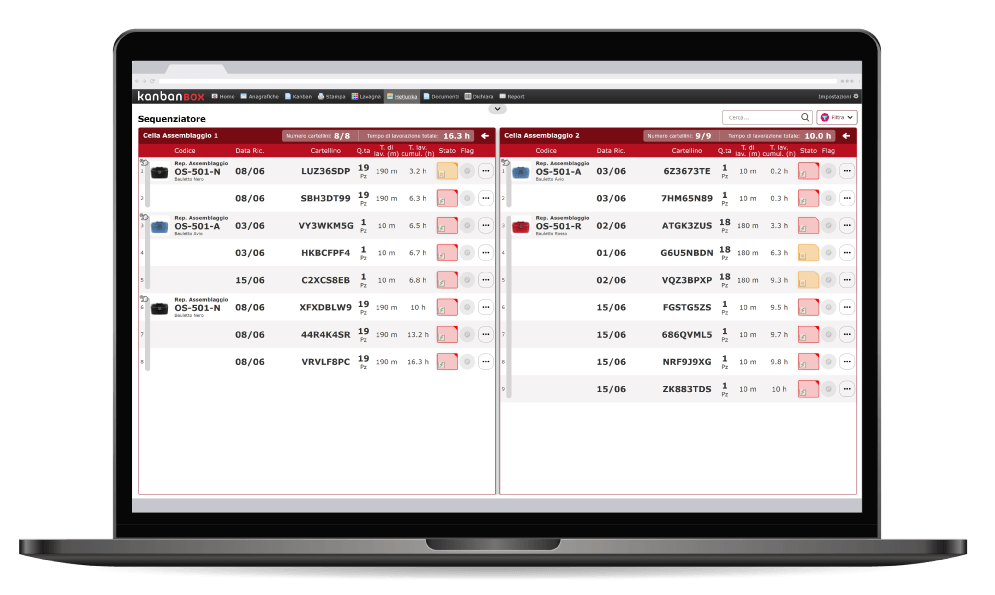

- Work plans are optimised by acting on the planning of finished finite capacity production (Sequencer), to establish the best sequences of operations.

The benefits for production

Managing production through KanbanBOX gives you the following advantages:

- Processing kanban orders with other production orders

- Automatically grouping production batches

- Obtaining visibility on workload and progress, monitoring the pace of progression in real time

- Avoiding overproduction

- Levelling with just one click

- Absorbing demand volatility.

Sequencer

Solve the complexities of manufacturing at finite capacity. The Sequencer is a Lean Manufacturing tool for planning the best sequences of operations on production machines. To make production truly efficient.

Find out moreHeijunka

Level with a click. This function allows the uniform distribution of daily and weekly workloads within the production cells. By displaying the information on the dedicated whiteboard, it adjusts the work rate of the individual operators, levelling picking and monitoring progress in real time.

Find out moreReferences

Case studies

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants and integrated KanbanBOX with SAP

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, and then integrated it with its own ERP, with the Oracle Sequencer and with the suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector