Connect KanbanBOX to the company's management system

Easily integrate the exchange of data with the company ERP and obtain BI data that is useful for your business

We do not replace your management system, but we can integrate it. To ensure the highest level of efficiency of all processes and the absence of errors, we can make our e-kanban management web interface with your ERP and communicate directly and in real-time. KanbanBOX is all you need to circulate information in a systematic way and create a lean and winning sales process!

KanbanBOX is a Supply Chain Collaboration software-as-a-service open to suppliers: it is a Cloud solution, which can be integrated with any management system. Keep the inventory accounting situation updated in real-time and collect Business Intelligence data useful for carrying out market research, analyzing competitive scenarios, and strategic information for your business. Discover the benefits of integration!

Instant adoption of the platform

automatic updating and analysis of data

Management software is the fulcrum of every business activity. KanbanBOX does not replace your management system but works with it to manage your Supermarket organized in kanbans. Buy, sell, produce and move components and materials more efficiently and in less time with KanbanBOX.

- Send your online orders to suppliers or internal departments

- Update and synchronize your stock status with one click

- Display and monitor the entire supply chain status in real-time

- Optimize data collection and carry out analyses, forecasts, and comparisons

- Read barcodes and send reminders from your smartphone with the KanbanBOX app for Android and iOS.

Connector for interfacing with SAP

KanbanBOX can be integrated with the most popular business management systems, while an interface is already available for companies that want to easily integrate it with their SAP systems. Working together with simplification and automation, keeping the system updated as volumes and consumption mixes change becomes quick and easy. No data is lost, the exchange of information becomes streamlined, and order processing and management time decrease.

Integration layer facilitated with Oracle

In improving its entire range offer of infrastructures, applications, and databases, Oracle has chosen KanbanBOX as a solution for the Lean management of material flows through electronic kanbans. The integration between Oracle Fusion Cloud ERP and KanbanBOX allows you to benefit from the collaboration and exchange of data in real time between the two systems to control the flows of materials within the Company and in the Supply Chain, monitor and maximize performance, achieve operational efficiency and optimize resources.

Integration with Microsoft BI power

Knowing how to collect data is not enough. The added value lies in knowing how to read it, seeking only that information that is really useful for decision-making processes. KanbanBOX exploits the potential of Power BI, the Business Intelligence software developed by Microsoft, to integrate its own statistics with new, more complex, and dynamic statistics. Able to analyze the data detected by KanbanBOX in more depth. Power BI automatically extracts stratified data, providing aggregate and dynamic statistics, which can be filtered as needed. Collecting BI data and implementing forecasting systems and building alternative scenarios has never been easier. Discover our Power BI integration packages!

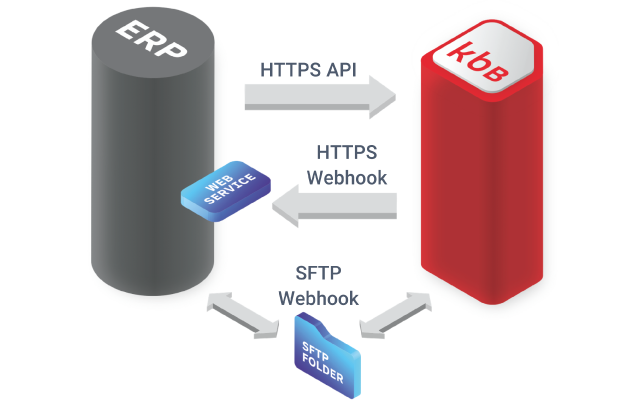

How integration works

The ERP queries KanbanBOX which provides it with all the updated information for the direct management of individual operations (creating links, creating cards, managing card statuses, managing personal data, etc.).

At each important event, KanbanBOX sends a notification to your ERP to manage production and purchase orders, update the warehouse accounting situation and collect BI data.

References

Case studies

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants and integrated KanbanBOX with SAP

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, and then integrated it with its own ERP, with the Oracle Sequencer and with the suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector