KanbanBOX and RFID: increase the performance of your company

Design, development and integration of identification systems with RFID technology

The RFID identification system opens up new perspectives in automation techniques, making the entire production and supply chain visible and automating the movement of goods and semi-finished products in warehouse departments, between different plants or even between companies that work continuously. Great visibility, speed, better control, high performance. Integration of the ekanban system with RFID technologies. Eliminate manual errors and downtime, accelerate processes and gain total control.

The evolution 4.0 of the electronic kanban

RFID reading systems are the most technologically advanced answer to application requests in the civil and industrial fields: in addition to the complete and real-time visibility of the flow of materials, the technology allows you to plan and control processes with precision and efficiency, arriving at the full automation of material flows.

KanbanBOX combines all the advantages of the electronic kanban with RFID technology for reading cards in radio frequency, which allows for the elimination of hardware reading devices. Thanks to the combined use of the two systems, electronic kanban + RFID, it is possible to maximise the Pull management of materials and the replenishment of the Supermarket, leading to a complete automation of the flow.

.

Higher performance in all work environments

An RFID system consists of a transceiver (Reader) and one or more Transponders capable of communicating with each other by means of a radio frequency modulated signal. An RFID area identifies an area in which, if a Card enters, it undergoes the same action. An RFID area can be a portal, a container or an area covered by one or more antennas, in turn managed by a Reader.

There are many fields of application for radio frequency identification technologies in the industrial, logistics or material handling fields, through the use of RFID transponders, RFID readers or RFID antennas:

- automatic identification of materials

- handling of goods and semi-finished products in the warehouse

- control of production lines

- automatic regulation of the flow of material within a production unit

- identification of pallets or containers

Equipping an area with RFID antennas allows you to recognise all the appropriately carded objects that pass through it, also recognising the direction of crossing (inbound or outbound material).

The types of RFID: eliminate manual reading

The types of RFID reading points to automate scans and free operators from manual reading operations can be:

- gates or passages for fixed or mobile stations (logistics trains) to read Cards from a few centimeters away up to 3 metres

- boxes for picking up from the shelf and boxes for storing empty containers

- antennas in different plants or companies that work continuously, to enable Intra and Inter-Company RFID.

Simplified integration with RFID Hardware

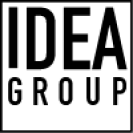

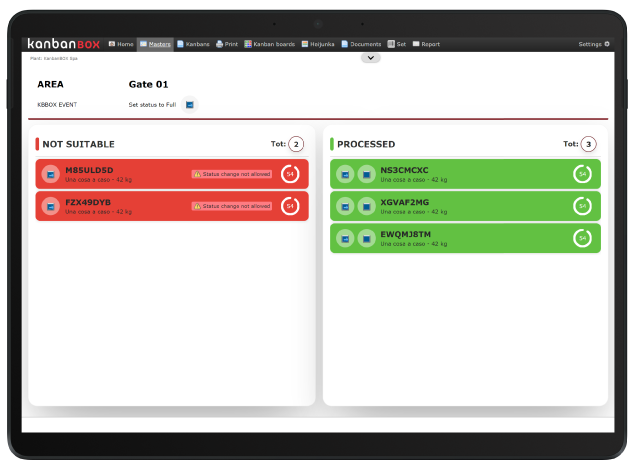

Thanks to the configuration of the RFID module in KanbanBOX and integration with RFID Hardware, when the material is identified with an RFID card, when it passes under the antennas, the system immediately recognises the content and direction of movement, updating, in real time, all the data relating to that lot in KanbanBOX. We provide you with:

- simplified integration

- control dashboard with the possibility of automatic reading or with manual confirmation

- technical support.

Case studies

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants and integrated KanbanBOX with SAP

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, and then integrated it with its own ERP, with the Oracle Sequencer and with the suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector

References