KanbanBOX for the management of internal logistics

How to optimise the supply chain

Planning, execution, control of the physical and information flow within the company. KanbanBOX is the software that helps you to optimise resources, processes and services, not only allowing you to achieve the maximum possible profit, but aligning the physical and information flow. So that everything is truly traceable and under control. By reducing waste, an essential element for controlling the supply chain.

With KanbanBOX lean logistics you can:

- Contextualize the physical and information flow

- Improve operations at all levels

- Optimise the supply chain by reducing waste.

The kanban to improve a production company's internal logistics

Efficient processes require an adequate internal logistical flow, to be as reactive as possible to changes in demand.

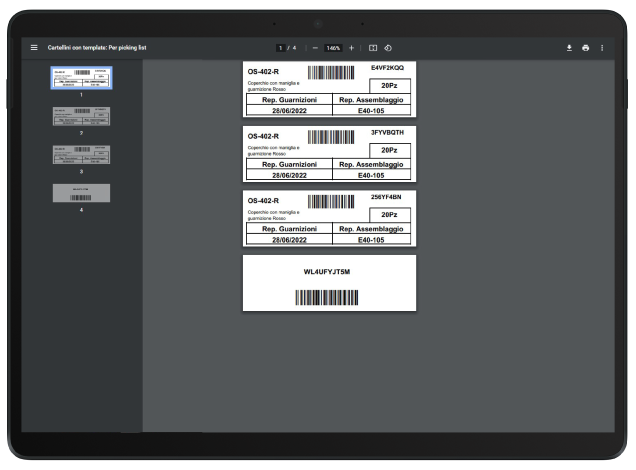

A supply system for internal company departments based on electronic kanban cards makes it possible to standardise supply, simplify the management of materials to supermarket warehouses and facilitate the process of picking and storing materials.

KanbanBOX guides the internal recovery processes, standardising and optimising logistics activities, replenishment of supermarkets, picking operations, the route of supply trains (Milk Run).

Eliminate or reduce waste related to transport, reworking and waiting. And once mastered from the inside, extend the system to customers and suppliers!

The Milk Run

Milk Run logistics management.

With KanbanBOX you collect the list of components to be replenished by reading barcodes and optimise picking and delivery routes.

Find out moreReferences

Case studies

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants and integrated KanbanBOX with SAP

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, and then integrated it with its own ERP, with the Oracle Sequencer and with the suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector