Data collection and analysis: why it’s a key advantage of e-kanban

Limits of manual kanban for data tracking

Manual kanban has always been an effective tool for managing production flows in a simple and visual way. However, it has one major limitation: it does not allow you to accurately track activities.

If a card gets lost, misplaced, or forgotten, it’s difficult to notice it in time. Likewise, in cases of delays, material shortages, or line stoppages, it’s not easy to understand where the issue occurred or what caused it.

Without tracked data, it becomes difficult to measure performance, identify bottlenecks, and improve processes.

That’s why switching to electronic kanban is a natural evolution: it maintains the lean logic of the method but adds visibility, traceability, and analytical capability.

Benefits of data tracking with electronic kanban

Unlike manual systems, electronic kanban makes it possible to track events and movements in real time. Every operation that takes place in the system is automatically recorded, allowing you to collect information on consumption, deliveries, replenishment times, status changes, and supplier performance.

These aggregated and constantly updated data become a valuable source for analyzing flow trends, identifying bottlenecks, and measuring the results of continuous improvement.

Electronic kanban therefore does more than manage material flow: it turns operational data into strategic information, providing complete and objective visibility over the entire production process.

How data tracking works in an electronic kanban system

In electronic kanban, each card is associated with a unique ID code, represented both as an alphanumeric code and as a barcode.

This code uniquely identifies each kanban card and allows the system to automatically record all events related to its lifecycle.

Every time a card changes status, for example, when an operator scans its barcode to report material consumption or to mark it as available upon receipt, the action is tracked by the software in real time.

Along with the card status, the system records a variety of additional information, such as stock levels, replenishment times, consumption and delivery dates, delays, and much more.

In this way, electronic kanban turns every operation into traceable, accessible data, ensuring complete visibility, full traceability, and detailed analysis of the entire kanban flow.

From data tracking to data analysis in an electronic kanban system

All electronic kanban software track (or at least should track) data related to card movements and material flows.

However, recording information is only the first step: what really makes the difference is the ability to turn that data into actionable insights that help make better decisions.

This is what separates a proactive production system from one that simply reacts to problems.

With KanbanBOX, the electronic kanban software used in more than 2,500 plants worldwide, companies have access to information such as:

- System performance statistics

- History of scans, status changes, and comments left on digital kanban cards to report issues

- Links between finished product kanbans and component kanbans, via the “Traceability” function

- Historical trends in consumption and average supplier lead times

In addition, companies can perform advanced analyses through two different tools:

- Integration with external data analytics software, such as Power BI, Microsoft’s data analysis tool, ideal for companies that need broader analyses combining kanban data with information from other business systems.

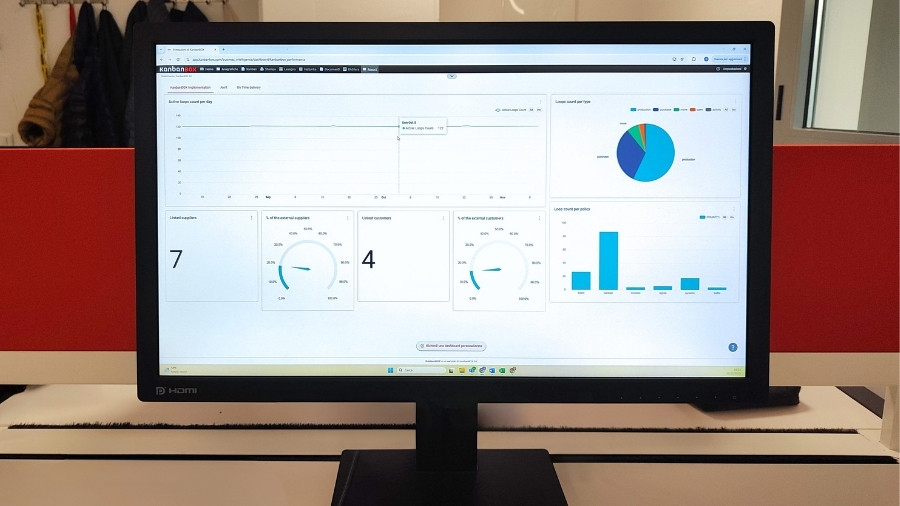

- Kanban Business Intelligence (Kanban BI), the platform’s native module, ideal for users who want ready-to-use, integrated, and real-time analysis directly within KanbanBOX.

Both systems are designed to meet the specific needs of each company, each offering its own strengths. We covered this topic in more detail in the article: Kanban BI vs. Power BI: which one to choose.

Depth of data analysis: a key criterion when choosing electronic kanban software

When evaluating electronic kanban software, it’s important to remember that a good system doesn’t just digitalize material flow: it also enables you to turn tracked data into meaningful information for continuous improvement.

That’s why, during the software evaluation phase, it’s crucial to assess which analysis and reporting tools the software offers, whether built-in or through integration, how in-depth they are, and whether they allow real-time data visibility.

Only then can you choose a solution that doesn’t just manage processes, but truly helps you understand, measure, and optimize them.

Want to learn more about KanbanBOX’s analysis features? Check out these related resources: