Questions and answers about electronic kanban (part 2)

This article, part 2 of a series, answers the most frequently asked questions about electronic kanban collected from companies, operators, and production and logistics managers. It’s a resource designed to provide clarity, dispel doubts, and help you better understand what an electronic kanban system is and how it works.

To make the most of this second part, it’s important to be familiar with the definition of electronic kanban. If you’re unsure, you can review it by reading Questions and Answers about Electronic Kanban (Part 1).

Do I need to already have a kanban system in place for years before setting up an electronic kanban system?

No, it’s not necessary. Transitioning from a manual kanban system to an electronic kanban system is typically faster because the core logic remains the same (pull logic).

However, it’s not uncommon for a company to move directly from a push system to a pull system with electronic kanban. In this case, with good process analysis and proper employee training, the transition can be smooth and natural.

Can electronic kanban be applied to a pilot line?

Yes, this is the recommended approach. The electronic kanban system is implemented for a single line or pilot project, and once the system is stable, it can be expanded to other lines or departments, gradually extending it to all desired processes, including production, purchasing, handling, and sales or distribution processes.

Does electronic kanban replace manual kanban?

No, it enhances it but does not replace it. Many basic kanban processes remain the same (e.g., reordering material only when the kanban container is empty or upon reaching the card batch).

Other processes, both low-value and high-value, will be digitized.

Let’s look at how the replenishment signal transmission changes when moving from a manual kanban system to an electronic one.

- With manual kanban, it’s necessary to detach the kanban card from the empty container, collect it with other kanban cards, bring it to the kanban board, and place it correctly so that it is delivered to the appropriate supplying process to signal the need for replenishment.

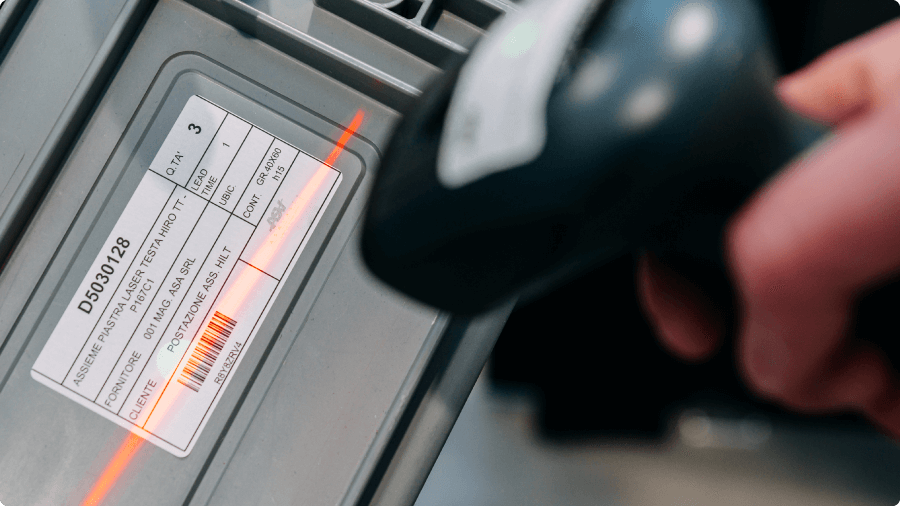

- With electronic kanban, the operator only needs to scan the barcode on the kanban card attached to the empty container. This will generate a new replenishment request for the supplying process. The operator of the supplying process will see the request in real time through a digital kanban board on a production monitor.

Are paper kanban cards still used in an electronic kanban system?

Yes, paper cards are still used. The difference is that, in addition to the printed card, there is also a digital version available through the software interface. This digital version provides additional information about the associated kanban, even without the paper card in hand: its status (to be replenished, available, in process, in transit), dynamic information not shown on the physical card (e.g., if its replenishment is delayed), and comments added by operators.

This information is tracked and analyzed by the software to identify material consumption data, calculate optimal kanban sizing, and generally provide valuable insights for more efficient and effective material and production management

How do you manage kanban sizing maintenance with electronic kanban software?

With dedicated features. Not all electronic kanban software includes this functionality, or not in a fully developed way. KanbanBOX, however, offers a dedicated feature that makes kanban maintenance simple and quick. By collecting and analyzing consumption data, it provides automatic suggestions for optimal kanban sizing, while leaving the final decision to accept or reject the suggestions to the responsible.

Why does the optimal kanban sizing suggested need to be approved by the manager?

For greater control. The optimal sizing calculated by the software must always be approved or rejected by a designated manager or operator to avoid operational issues. A simple but representative example: the software may suggest a larger lot size to optimize replenishment, but the company might not have the physical space to store it, or there could be constraints related to handling, safety, or other factors that only someone familiar with the production context can properly assess.

Does electronic kanban help optimize inventory levels?

Yes, through inventory control. With electronic kanban, you always have a clear and real-time view of items being consumed, in transit, or needing replenishment, improving inventory management. Moreover, thanks to the kanban maintenance feature, you can update the kanban sizing based on actual consumption trends, reducing the risk of overstocking or stockouts.

Finally, by adding so-called “extra kanban” cards to handle demand peaks, you can effectively manage product seasonality without impacting consumption statistics.

How does replenishment signal transmission work in an electronic kanban system?

Digitally, through barcode scanning. The process works as follows:

- The workstation operator finishes a kanban container and scans the barcode on the kanban card attached to the container.

- This scan digitally transmits the information to the software, which updates the data across all digital boards, including the board of the supplying process responsible for replenishment.

- The operator of the supplying process sees the replenishment request through the digital version of the kanban card, with all necessary information for replenishment.

- Once the material is ready, the supplying operator prints the kanban card and attaches it to the kanban container, ready for delivery to the workstation operator.

Can I integrate external suppliers into the kanban system using electronic kanban software?

With some software, like KanbanBOX, yes. With others, no. KanbanBOX allows you to integrate external suppliers so they can view replenishment orders on a dedicated board within the software, just like internal processes. This is made possible by the digital transmission of the replenishment signal, which lets you send the order in real time to suppliers in other cities, countries, or continents.

Is electronic kanban suitable only for production, or also for logistics and purchasing?

It is useful across the entire supply chain. E-kanban connects logistics, production, and purchasing, ensuring coordination, visibility, and speed throughout the procurement process. It can be applied to just a portion of processes or the entire supply chain, depending on your needs. You can also start with a single line or process and later expand to other areas. To discover more about this topic, book a call with our experts: we will answer to all your questions!

What is the best electronic kanban software?

It depends on the company’s needs. Among the top players is KanbanBOX, chosen by both SMEs and large multinational groups, all over the world, for its flexibility, simplicity, and ability to integrate with existing systems and suppliers.

For more information, contact us. Our consultants are ready to answer your questions and help with your specific needs.