Extending the benefits of kanban beyond the factory boundaries

The Story of Gilbarco, saving 20 hours per week in material management along the supply chain

Highlights: Purchase Kanban with Suppliers | Move Kanban | Production Kanban | ERP Integration | Power BI Integration | Technical Drawings | Intercompany Kanban

Gilbarco Veeder-Root, a leader in the fuel distribution sector, operates a vast and complex production system with facilities worldwide. At its headquarters in Greensboro, North Carolina, the organization faced significant challenges.

One of the main challenges involved coordinating material flows between an external warehouse (located just a few kilometers from the plant), the internal central warehouse, various production lines, and multiple external suppliers. This logistical setup required constant monitoring and precise coordination, but the available tools (an electronic kanban software that could not integrate with the ERP) made everything more difficult.

To eliminate these inefficiencies, Gilbarco adopted a more advanced e-kanban software, KanbanBOX, which integrates seamlessly with the ERP.

Overview of Gilbarco Veeder-Root

Since 1865, Gilbarco has been a benchmark in innovation for the fuel distribution sector. The company manufactures fuel dispensers, alternative energy equipment, and equipment for convenience stores at service stations, boasting a long history of innovation. From creating the first gasoline measurement pump to introducing the Multi-Product Dispenser and launching the first integrated contactless reader for service stations, the company has consistently redefined industry technological standards. This commitment to innovation was strengthened in 2002 by the merger between Gilbarco and Veeder-Root, and in 2020, by joining the Vontier group.

Today, with headquarters in Greensboro, North Carolina (USA), and a global manufacturing and distribution presence, the company continues to invest in digital and advanced automation solutions. In this continuous improvement journey, the decision to adopt KanbanBOX supports the efficiency of their logistics and production flows.

Initial situation: an e-kanban system that couldn’t integrate with the ERP

Before switching to KanbanBOX, the Greensboro plant used a US-made electronic kanban system, but it wasn’t integrable with their ERP. This forced the team to manually enter data into separate systems. This double-entry not only took time but also introduced the risk of errors, delays, and inefficiencies throughout the material replenishment process.

As a result, Gilbarco managed far fewer items with e-kanban than they would have liked to manage with a pull method.

Beyond that, the company faced significant complexity in managing replenishment activities as they had to coordinate:

- Material flows between the central warehouse (internal) and the external warehouse located a few kilometers from the plant, a common practice among large companies.

- Multiple production lines.

- Numerous external suppliers.

The legacy e-Kanban as a source of MUDAs (wastes)

Determined to turn things around, Gilbarco searched for an alternative solution that would also meet several needs, which were addressed by KanbanBOX features.

- Automatic calculation of kanban card resizing based on daily demand:

with the previous e-kanban software, they had to manually analyze consumption to keep kanban cards aligned with actual needs. With KanbanBOX’s maintenance functionality, this calculation is automated using sophisticated algorithms and updated based on actual consumption. - Disposable or virtual cards for quick resizing: with reusable cards, operators spent a lot of time searching for the card that needed to be removed or reprinted. With KanbanBOX, the company uses unique, disposable cards for each kanban container, allowing for easier management of kanban cards and related information (when a container is emptied, the barcode is scanned, and the card is discarded).

- Goods receipt integrated with the ERP:

With the previous system, when new goods arrived, the operator had to perform a double operation—first entering the product code in the e-kanban software, then in the ERP. With KanbanBOX, which integrates with any ERP, this operation was replaced by a simple barcode scan (once only, using dedicated scanning devices or a smartphone with the KanbanBOX app), which then updates the article code in both the KanbanBOX digital board and the ERP.

Once it was verified that KanbanBOX met the required specifications, Gilbarco’s representatives visited another KanbanBOX customer, Interroll, to see the software in action. With the last doubts cleared, the company decided to proceed with the implementation of the software.

Implementing KanbanBOX: from internal kanban to kanban with suppliers

Before adopting KanbanBOX, the Greensboro plant did not have any standardized processes:

- Suppliers sent goods in varying quantities.

- There were no clear or shared guidelines for where components should be placed.

- There was no shared procedure for when to request material replenishment.

The implementation of KanbanBOX in 2023 changed all of that, leading to the establishment of a standardized collaboration method both among internal processes and departments and with external suppliers.

Gilbarco standardizes the collaboration processes along the supply chain with KanbanBOX

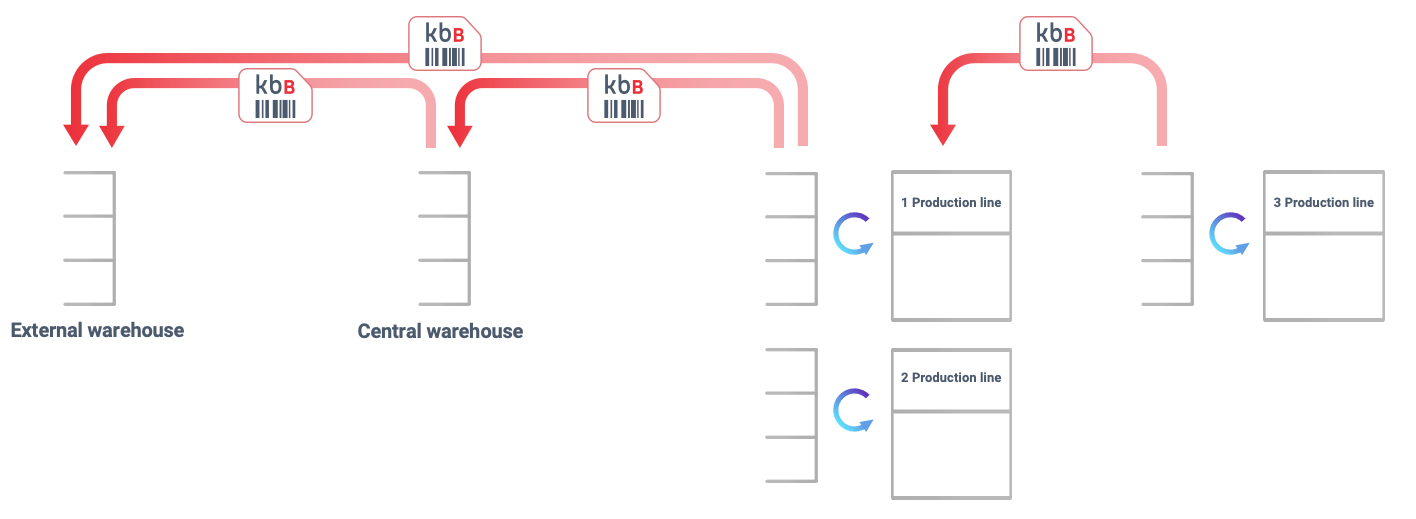

First, they implemented an internal kanban, more precisely a move kanban, to manage the transportation of components from the external warehouse to production and/or from the external warehouse to the internal central warehouse.

Next, the integration between KanbanBOX and the ERP software used by Gilbarco, Microsoft AX, was completed.

In 2024, the electronic kanban system was extended to the rest of the supply chain, meaning external suppliers (the so-called “kanban with suppliers” or “purchase kanban”).

A connected and integrated production system

In summary, with the implementation at the Greensboro plant, the company used KanbanBOX to connect:

- External warehouse and central warehouse.

- External warehouse and production lines.

- Different production lines among themselves.

- Material flows through KanbanBOX at Gilbarco.

Situation one year after implementation, in Greensboro and other locations, both in the USA and abroad

In just over a year since the software implementation, Gilbarco was managing approximately 5,000 parts with KanbanBOX.

This number demonstrates how easy the company finds KanbanBOX to use. It allowed them to independently implement many of the numerous internal kanbans at the Greensboro plant.

Meanwhile, Gilbarco decided to extend the use of KanbanBOX to other plants. To do so, they held a “Group Leader” course, where KanbanBOX specialists trained two key figures at Gilbarco to guide the independent implementation of KanbanBOX in a peer-to-peer mode.

With this foundation, in 2024, KanbanBOX was implemented at other Gilbarco facilities: the Angi Energy System (Gilbarco brand) plant in Janesville (internal kanban), São Paulo, Brazil (internal kanban), and Salzkotten, Germany (kanban with suppliers).

Another facility where it was implemented is Altoona, Pennsylvania. This plant uses KanbanBOX for internal kanban, production kanban, and kanban with suppliers. Specifically, at this plant, KanbanBOX helps Gilbarco manage approximately 17,000 kanban cards for 4,000 part codes.

Additionally, a pilot project is underway at this facility to gradually replace the current ERP with a new company ERP, Microsoft Dynamics 365, while maintaining integration with the ERP (since KanbanBOX is not tied to the company’s management system).

“Using KanbanBOX, we have created several tug routes to deliver material internally. We use the kanban statuses to track on time delivery, and use the system to see where material is within the factory. The material handlers can quickly scan material, while management can simply track the efficiency metrics.”

Lakosha Whitson, Materials Supervisor, Gilbarco Veeder-Root

The intercompany Kanban at Gilbarco

Gilbarco successfully extended the use of electronic kanban to several of its facilities abroad, particularly to one of its main European sites in Salzkotten, Germany.

In this context, the intercompany kanban was implemented, operating under the same logic as kanban with external suppliers, with one key difference: the “supplier” is another company or facility within the group. Specifically, the Altoona (USA) plant serves as a supplier of components for the Salzkotten (Germany) site, creating a structured and fully digitalized flow between the two locations.

Both sites use KanbanBOX to monitor the status of orders and kanban cards in real time: when the Salzkotten site releases a kanban to request material, the Altoona site immediately sees the update on its digital board, allowing it to start preparing and shipping components without delays or manual communication. This model enables instant alignment, greater transparency, and more efficient management of the internal supply chain.

Featured functionality: How Gilbarco uses the “Technical Drawings” module

The situation was as follows: for some plants, Gilbarco wanted to print assembly instructions along with the related kanban cards.

To achieve this, they decided to adopt the KanbanBOX “Technical Drawings” module. The purpose of this functionality is to link a specific item code to one or more files, whether PDF or others (CAD, procedures, etc.), that can be accessed by the operator directly from the kanban card in the digital board.

The files are stored in a cloud repository (client FTP folder, Amazon S3 Bucket, Intranet WEB Server, or other) and managed in such a way that when a technical drawing, procedure, or other associated file needs to be updated, it can be done with a few clicks, cascading to all kanban cards associated with that component, avoiding the risk of some cards still being linked to the old version of the file.

Integration Highlight: Data analysis with Power BI and focus on inventory levels

Gilbarco uses Microsoft Power BI as its central tool for monitoring and analyzing business data, and KanbanBOX for managing the e-kanban system, including inventory levels (the “Inventory” feature). Through integration between KanbanBOX and Power BI, the Inventory feature of KanbanBOX has been directly embedded in their dashboards.

This was made possible through the development of specific APIs that automatically send the relevant inventory rows to Power BI, ensuring constant updates, eliminating inconsistencies, and providing a unified, accurate, and end-to-end view of the entire material replenishment system.

This means that Gilbarco has chosen to use KanbanBOX as the sole official source for all inventory-related information to ensure consistency and reliability in stock-related analyses, with a view toward greater data integration and transparency.

“KanbanBOX gives us the tools to efficiently deliver material internally between warehouses, supermarkets, and point of use locations as well as monitor inventory levels between our factory and external suppliers. From KanbanBOX’s data and reporting, we can better understand our inventory levels and drive reduction across the factory.”

Patricia Okraski, Lean Business Systems Manager, Gilbarco Veeder-Root

Key results: Gilbarco saves 43 days per year thanks to KanbanBOX

So far, Gilbarco manages over 11,000 part numbers in KanbanBOX, organized into three different types of kanban (internal or move kanban, production kanban, purchase kanban), in addition to the intercompany kanban between facilities.

The introduction of the software has had a significant impact on productivity: the time to place a purchase order dropped from 44 seconds to just 2 seconds. Considering the company generates about 1,700 orders per week, this improvement translates into a huge time savings, up to 20 hours per week, equivalent to 43 workdays per year.

This result frees up resources, reduces operational load, and allows teams to focus on higher-value activities.

These results clearly demonstrate that with the right tools, even the most complex processes can be made efficient. The combination of a digitalized kanban management system, full data integration, and standardized flows not only simplifies complex activities but also delivers tangible savings, increased operational reliability, and continuous visibility across the entire supply chain.

The Gilbarco case study published on Planet Lean

The case study on the implementation of electronic kanban at Gilbarco has attracted attention outside the company: it was published on Planet Lean, an important international publication dedicated to lean thinking and its practical applications.

Publication on such an authoritative platform confirms the value of the project and recognizes the tangible impact that process digitalization has generated in Gilbarco’s supply chain.

You can read the article at the following links:

“This E-Kanban system provides greater visibility, communication, and process enhancement between customer and supplier. We have simplified the ordering process to allow more time for continuous improvement.”

Luke Mcgann, External Planner, Gilbarco Veeder-Root

Does your company face a complex situation?

Contact us: Together, we’ll determine if KanbanBOX is the right solution for you.