Optimizing inventory and multiprocess production orders with Synchro cards

The story of Oleodinamica Marchesini, which accelerated its Lean transformation journey with KanbanBOX

Highlights: Production Kanban | From Kanban to Make to Order | ERP Integration | Synchro Cards | Multiprocess

Manual kanban is an excellent tool for managing production, but it becomes less efficient when it comes to handling multi-process productions orders involving multiple interconnected production stages within a single flow. To overcome this challenge, which was hindering the company from reaching its goals in terms of lead time and inventory levels, Oleodinamica Marchesini adopted KanbanBOX. This transition allowed them to gradually move toward a Make to Order production system, unlocking new efficiencies and enabling them to meet their operational targets.

Overview of Oleodinamica Marchesini

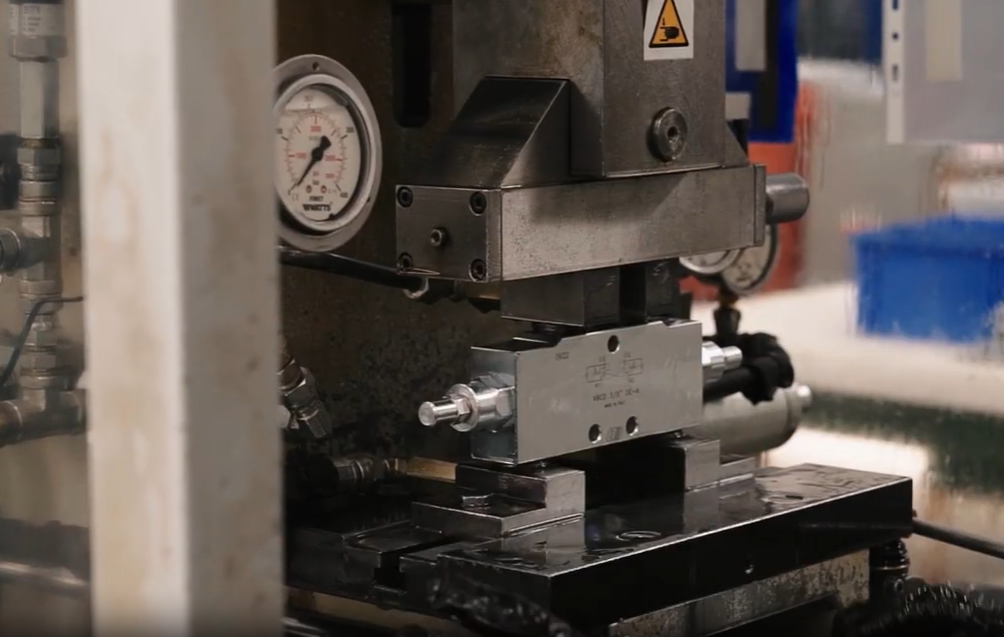

Oleodinamica Marchesini is a company with over 40 years of experience, specialized in the production of hydraulic valves for agricultural lifting machinery, earth-moving equipment, construction, and municipal applications. Over the years, the company has established itself in both national and international markets and is part of the OM Group, together with Naldoni e Biondi and Fluid World.

In recent years, Oleodinamica Marchesini has embarked on an important Lean improvement journey, with several objectives including stock reduction. In 2025, thanks to the adoption of the KanbanBOX software, the company achieved results that, in their own words, had previously seemed out of reach.

Starting point: manual kanban with magnetic cards

At its plant in the province of Brescia (Italy), Oleodinamica Marchesini had been managing materials using a manual kanban system with magnetic cards and physical boards.

Switching from a traditional “push” approach (planned based on sales forecasts) to a kanban system had already enabled a significant reduction in inventory.

However, after months of gradual and consistent warehouse space reduction, the company had reached a standstill.

This was due not only to the typical limitations of manual kanban and to management policies (kanban cards were not linked to individual boxes but to a layer of pallets, e.g., 12 boxes), but also to the presence of multiple production steps in flow (so-called multiprocess).

With manual kanban, it was not possible to effectively link the various phases of the numerous production steps (e.g., laser marking). As a result, despite efforts to make these processes “pull” (triggered by actual consumption) production remained essentially make to stock.

This led to the need for a solution that could overcome the standstill and continue the improvement journey toward a true pull system.

“While doing research online, we found a video from a KanbanBOX customer describing how the software helped them manage their multiprocess workflows, very similar to our situation.

That’s when I looked into it, we contacted them, and shortly after, we started the implementation.”

Massimiliano Uberti, IT Manager, Oleodinamica Marchesini

Implementing KanbanBOX

After confirming that the software met their technical and functional requirements (intuitive interface, ease of use, ISO 27001 certification, and a modular, flexible pricing model), the company launched an initial implementation on a pilot line, not large in terms of item codes, but comprehensive in terms of process.

Following this test phase, the company accelerated rapidly: in just a month and a half, KanbanBOX was adopted for all high-rotation items, which alone generate half of the company’s revenue. The usage was then progressively extended downstream, toward the warehouse, and upstream, to include low-rotation items as well.

“We reached our goals much faster and more thoroughly than expected. As we explored the software’s capabilities, we realized how many new opportunities opened up and how much they benefited production management.”

Dino Falciola, CEO, Oleodinamica Marchesini

ERP integration and multiprocess management

The introduction of KanbanBOX deeply transformed the company’s operations.

For example, an integration was set up with the existing ERP system, Microsoft Navision: when an order enters the ERP, it is automatically sent to KanbanBOX.

- If the order is managed with a single-step kanban, KanbanBOX generates a production kanban.

- If the order requires sequential processing steps, multiple cards are generated, one for each step, using the multiprocess kanban.

The multiprocess kanban is a KanbanBOX feature that allows companies to link several production steps in a single flow, generating as many order cards as there are steps. This way, the phases are connected: once the upstream step is completed, the downstream step can begin.

Thanks to this feature, Oleodinamica Marchesini was able to link multiple production phases and automatically trigger each step in the multiprocess flow without intermediate supermarkets, moving toward a sequential pull system.

The game changer: Synchro cards for closed-loop orders

As Oleodinamica Marchesini optimized its processes and explored more of the software’s features, it discovered new functionalities and improvement opportunities that gradually expanded the original project.

Among the key innovations was the use of Synchro cards, which (unlike traditional kanban cards) do not automatically trigger a replenishment order when consumed. Instead, they support a single-cycle procurement process.

Using Synchro cards enabled the transition to a Make to Order (or Assemble to Order) model, making operations leaner and more responsive.

One tangible result of this shift was the near-elimination of picking activities: once assembly is complete, operators can place the material directly on the shipping pallet, significantly reducing stock while still meeting order requirements within just a few days.

“For our highest-rotation item, I thought it was unavoidable to keep at least 200 boxes in stock. With KanbanBOX we went well below that: first to 93, then to 14, and soon we’ll reach just 2 boxes. We produce the same quantity as before, but now the hundreds of other boxes are shipped to customers as soon as they’re assembled, completely eliminating storage.”

Dino Falciola, CEO, Oleodinamica Marchesini

Results after the first 6 months of KanbanBOX implementation at Oleodinamica Marchesini

Thanks to KanbanBOX, the company was able to improve operations, reduce lead time, and lower the need to stock items by eliminating unnecessary storage.

- Inventory value: –€1 million (the space previously used to store only the top-selling item now accommodates half of the company’s revenue)

- Annual inventory turnover: +1.5 rotations. The goal is to reach 8 by the end of the year, 10 by the end of the first quarter of the following year, and 12 in the medium term.

- Lead time: –7 working days on average throughput time, despite already having a strong service level, with deliveries within 3 weeks.

- Enablement of previously unthinkable Make to Order / Assemble to Order scenarios.

“For us, KanbanBOX was the enabler of a true Lean transformation. It’s like removing the cage from a bottle of Champagne: without that cage, the cork will eventually pop. Likewise, KanbanBOX has unleashed both our processes and our mindset. Today we are fully pull: we do nothing that isn’t driven by a sale.”

Dino Falciola, CEO, Oleodinamica Marchesini

Next steps: extending the model across the supply chain

After achieving strong results internally, Oleodinamica Marchesini is planning to expand its use of KanbanBOX across its supply chain. The next goal is to strengthen ERP integration and extend the model downstream (engaging customers in the replenishment flows) and upstream, by integrating machining operations for even smoother material management.

Looking ahead, the company also aims to include commercialized products, with the goal of creating a connected digital pull system that synchronizes all process stakeholders in real time.

Read the interview

To learn more about Oleodinamica Marchesini’s Lean Transformation journey, read the interview with Dino Falciola, CEO, and Massimiliano Uberti, IT Manager, who led the implementation within the company.

Go to the interviewKanbanBOX for you

To learn more about Oleodinamica Marchesini’s Lean Transformation journey, read the interview with Dino Falciola, CEO, and Massimiliano Uberti, IT Manager, who led the implementation within the company.