Why KanbanBOX is a pull system (beyond e-kanban)

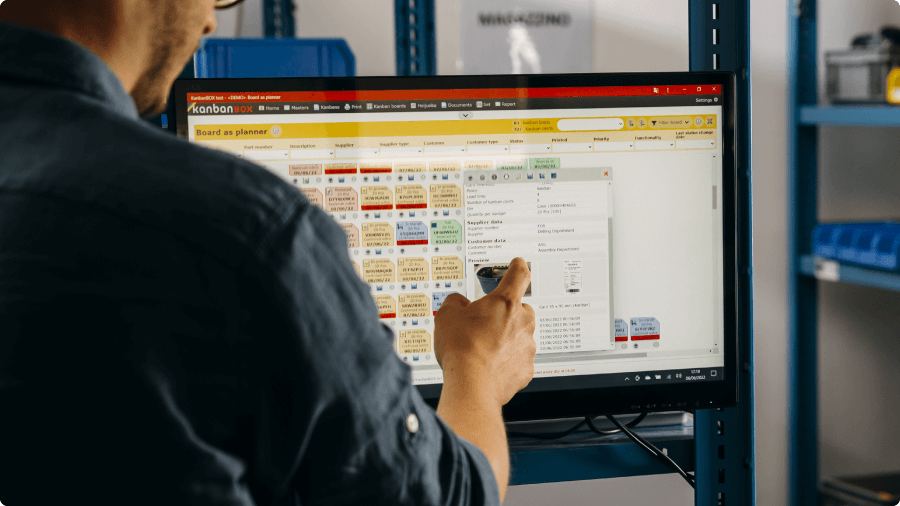

Many companies first approach KanbanBOX assuming it is “just” software for implementing an electronic kanban system, useful for digitizing card-related information and managing kanban flows more efficiently. But once they begin using it, they are surprised by the many additional features available.

They soon realize that KanbanBOX goes far beyond kanban, offering tools to manage the entire pull logic of materials and supporting different operating modes, from Make to Order (production on demand) to procurement (supplier and purchasing management), all the way to production scheduling.

It is at this point that KanbanBOX reveals its true nature: not just an e-kanban tool, but a complete platform for pull-based material management, designed to build a pulled, integrated, continuously improving flow throughout the supply chain.

Let’s take a closer look.

Pull material management with both kanban and closed orders

KanbanBOX is software for pull-based material management. This means it supports a production model in which the flow is driven by real demand, not by forecasts or static plans.

In a pull system, each process produces or supplies only what is needed by the next process, exactly when it is needed, preventing accumulation, waste, and inefficiencies.

To meet different production or procurement needs, the company can use KanbanBOX to manage both kanban orders and closed orders, all within a single platform.

This way, the company always has a clear picture of orders and inventory levels, understanding that repetitive products are generally best handled with kanban, while low-volume, high-mix products are more suitable for closed orders.

You can learn more about how KanbanBOX enables mixed management of kanban and closed orders in this article.

Pull production scheduling with the Sequencer

The Sequencer is the KanbanBOX tool that helps companies plan and optimize production flows by assigning production cards (kanban or closed-order) to different resources (work cells, machines, departments, etc.) and displaying them as a sequence.

Each card enters the work sequence only when it is required, keeping the flow synchronized with the real rhythm of the production system.

In this way, the Sequencer makes it possible to visualize, organize, and manage production priorities based on pull signals coming from downstream processes, such as replenishment requests or customer orders, facilitating the scheduling of cards across production resources and balancing workloads.

The Sequencer is therefore a tool that translates pull philosophy into daily practice, enabling a continuous, balanced, waste-free flow.

Pull production leveling with Heijunka

Heijunka is a Japanese term meaning “leveling,” referring to a Lean Manufacturing strategy aimed at reducing fluctuations and spikes in production workload, creating a more stable and regular flow.

In KanbanBOX, Heijunka represents an important element of pull-based production management, as it allows companies to level production (in terms of both volumes and product mix) according to real demand, keeping the flow steady and consistent.

This is essential because irregularity in workload (known as Mura in Japanese) creates overburden on resources and has a strongly negative long-term impact on process performance.

Leveling production helps avoid peaks, overburden, and downtime, while increasing customer service levels.

The result is a production flow pulled by demand, delivering stable and predictable lead times.

Multiprocess: a pulled flow from upstream to downstream

Another powerful pull tool in KanbanBOX is multiprocess management.

When a product is requested, the software doesn’t just generate the production request for the finished item: it also automatically activates all cards needed to produce, process, or procure the components and semi-finished articles requested.

This means every stage of the process, from the most upstream supplier to the most downstream workstation, is pulled directly by real demand, creating a fully synchronized flow with no inter-process inventory.

This automation allows multiple departments and processes to be coordinated naturally, without manual planning, ensuring each activity is triggered only when needed and in the right quantity.

It is the most concrete expression of the pull principle applied across the entire value chain.

Additional tools supporting pull system objectives

The ultimate goal of any pull production system is to perfectly align production with real demand, eliminating waste, and making the material flow smooth, continuous, and responsive.

To achieve this, KanbanBOX offers several advantages, including:

- Continuous, shared visibility with suppliers and internal departments

Through a shared digital board, the platform allows all supply chain actors (internal and external) to view inventory, consumption, and card status in real time, enabling informed, data-driven decisions.

- Integrated supply chain

With KanbanBOX, you achieve a truly integrated supply chain, where real consumption triggers order requests transmitted to suppliers and subcontractors in a simple, standardized, and immediate way.

- Integration with company systems and automation

KanbanBOX integrates with ERP systems, WMS, RFID, Business Intelligence tools, and more, to automate and streamline many activities, from order generation to data collection and analysis, reducing non-value-added manual tasks and improving overall operations and efficiency.

Why KanbanBOX being pull software (and not “just” e-kanban) is a major advantage for clients

The fact that KanbanBOX is not “just” e-kanban software, but a full 360° pull system, is a major advantage for clients.

Beyond the individual features, each of which a company can adopt as needed, the real value lies in the flexibility and ability to evolve that pull logic makes possible.

Often, companies adopt a tool because it fits their immediate needs, only to become constrained later by rigid systems that cannot grow along with them.

This is not the case with KanbanBOX: since it is a platform designed for pull-based material management, it can adapt and transform alongside the company, supporting it at every stage of its Lean journey.

A clear example is Oleodinamica Marchesini, which initially adopted KanbanBOX to digitize its manual kanban system.

However, as the company discovered the software’s capabilities, it realized it could go further, evolving toward a production model that is almost fully Make to Order, a goal that had previously seemed out of reach.

We started out wanting to digitize our kanban flows, but as we discovered the software’s potential, we realized we could go further, toward a production system fully pulled by demand through a Make to Order logic… and we did it.

The results speak for themselves: to manage our highest-turnover item, we had about 600 boxes in stock with the manual kanban. With electronic kanban (KanbanBOX), we reduced it to 93 boxes. With the shift to Make to Order, we are now at 14 boxes, and soon we will reach 2.

We produce as much as before, but now, with Make to Order, the hundreds of remaining boxes are shipped directly to customers as soon as they are assembled, eliminating almost entirely the storage phase.

Dino Falciola, CEO, Oleodinamica Marchesini

You can explore the complete Oleodinamica Marchesini case study, including many additional results, on the dedicated page at this link.

Do you want a supply chain that is increasingly lean, integrated, and value-driven?

We’ll explore together whether and how KanbanBOX can help you achieve your goals.