E-kanban: what it is, benefits, definition

By Francesco Dall'Oca

The material replenishment method in manufacturing and commercial companies

E-kanban: definition

E-kanban is a system made up of processes and tools designed to automate material replenishment in manufacturing or commercial companies.

Specifically, using e-kanban software helps simplify and speed up replenishment activities by reducing manual tasks and improving operational efficiency.

This system can be applied in various areas to:

- Reorder materials from external suppliers (procurement/purchase e-kanban)

- Manage internal movements between departments or warehouses (movement e-kanban)

- Organize production, even in multi-process flows, ensuring that each operator has the right components at the right time to carry out the required operations (production e-kanban)

- Manage the sale or distribution of products/components to customers or other plants (sales/distribution e-kanban)

Material replenishment system: what is it?

E-kanban is a material replenishment system, meaning it is a set of processes and tools used to ensure that material stock needed for production or sales is replenished in a timely and efficient manner.

The main goal of this system is to maintain a continuous flow of materials throughout the supply chain, avoiding both stockouts and excessive inventory buildup.

More specifically, e-kanban is a pull-based replenishment system. Pull management means that replenishment is triggered only when there is actual consumption (e.g., a container of materials is emptied and needs to be restocked). This is the opposite of the traditional push system, where the quantity of materials to order is predetermined by company planners based on sales forecasts or fixed schedules.

To better understand, let’s imagine a company managing the restocking of a component needed in production (e.g., aluminum tubes) using either a push or pull logic.

- In a push system, restocking is based on forecasts: the company plans orders in advance, but if actual usage differs from estimates, there’s a risk of either overproduction or shortages. Additionally, the number of tubes in stock must be monitored manually and data updated frequently.

- In a pull system, restocking is triggered only when the tubes are actually consumed, allowing the process to dynamically adapt to the real pace of production.

Automated replenishment system: what is it?

E-kanban is an automated replenishment system because, through dedicated software, it digitally and systematically manages material reordering with minimal human intervention.

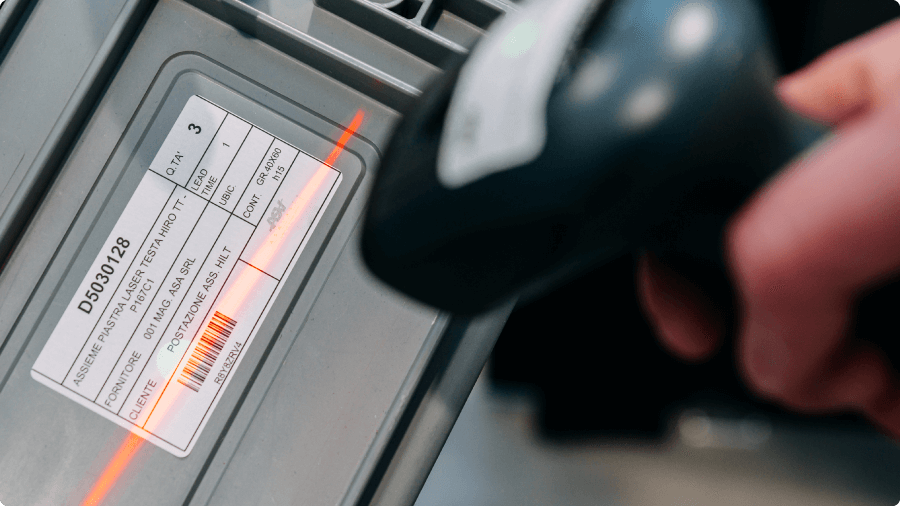

In practice, when an operator empties a container of material (technically, “consumes/deploy the material”) and needs to reorder it, there’s no need to fill out forms or inform a supervisor.

Instead, they simply scan the barcode on the kanban card attached to the container using a handheld device or scanner. The e-kanban system then automatically generates a replenishment request, which is instantly sent to the supplier or responsible department, including all necessary information for preparing and delivering the material.

This automation goes beyond just triggering orders. It also allows users to:

- Track stock levels and consumption in real time.

- Use a digital board to monitor the status of all orders and activities.

- Share the board with suppliers and partners involved in the replenishment process, improving transparency, coordination, and communication.

- Access data, statistics, and automatic recommendations from the software to optimize inventory management and processes.

Why more and more companies are adopting it: the benefits

More and more companies are turning to e-kanban to improve material management, reduce waste, and boost competitiveness. Whether in production, procurement, or logistics, e-kanban allows businesses to operate in a more agile, streamlined, and controlled way, supporting continuous improvement and long-term efficiency.

The key benefits include:

- Real-time visibility over consumption, inventory, and order status, enabling more accurate management and faster decision-making

- Greater operational efficiency: by automating certain manual tasks, e-kanban optimizes time, resources, and costs while eliminating the errors often linked to traditional management of purchase, production, movement, and distribution orders

- Easy integration: the system connects with ERP, WMS, MES, RFID systems, and automated warehouses, creating a connected ecosystem that’s ready for your company’s digital future

- Integration with customers, suppliers, subcontractors, and partners: sharing real-time data with external partners enables a synchronized supply chain, improving reliability and delivery performance

- Scalability and flexibility: the system easily adapts to changes in volume, demand, or internal organization, including the adoption of new software or Industry 4.0 technologies, making it suitable for both SMEs and large industrial groups

Learn more

In an increasingly dynamic and competitive market, e-kanban is the ideal solution for companies looking to enhance responsiveness, reduce waste, and manage materials more intelligently. With tools like KanbanBOX, a software platform that enables complete, modular, and easily integrated e-kanban systems, all this becomes possible.

To Explore the Topic Further, You Can:

- Schedule a free call with our experts

- Download our e-kanban guide to learn more about the benefits of this solution

- Read related blog posts, such as “What Is Kanban: A Definition Based on Its Use Context” covering kanban cards, kanban containers, kanban boards, kanban software, and more

- Follow us on LinkedIn