E-kanban manufacturing: why it's the seamless production tool

By Matteo Biagini

In manufacturing companies, kanban method is ideal for implementing a pull production system, where the consumption of materials directly triggers their replenishment (e.g. requesting its production from another work cell).

This ensures that production is always aligned with actual demand, minimizing overproduction and unnecessary inventory buildup. By eliminating the need for speculative forecasting and responding only to real-time needs, pull production with kanban system enhances efficiency and reduces waste.

This means classic kanban system is an excellent solution for managing the production flows of manufacturing companies. At least as long as the processes remain simple, the number of components is limited, operations are confined to a single plant without multi-site or third-party processing, and the supplier base is small. Indeed, as complexity increases, companies face two choices:

- Continue using the traditional kanban system, relying on manual oversight to address inefficiencies, delays, and errors caused by the increased complexity

Or - Upgrade to e-kanban manufacturing system, leveraging automation, real-time tracking, and digital integration to maintain efficiency and control in a more complex environment.

E-kanban manufacturing system: what it is?

E-kanban manufacturing system is an e-kanban system implemented in manufacturing companies. E-kanban, abbreviation of “electronic kanban”, indicates a kanban system made even more efficient thanks to the advantages of digitalization.

In fact, by digitalizing the information processes of the traditional kanban system, the e-kanban manufacturing system allows companies to:

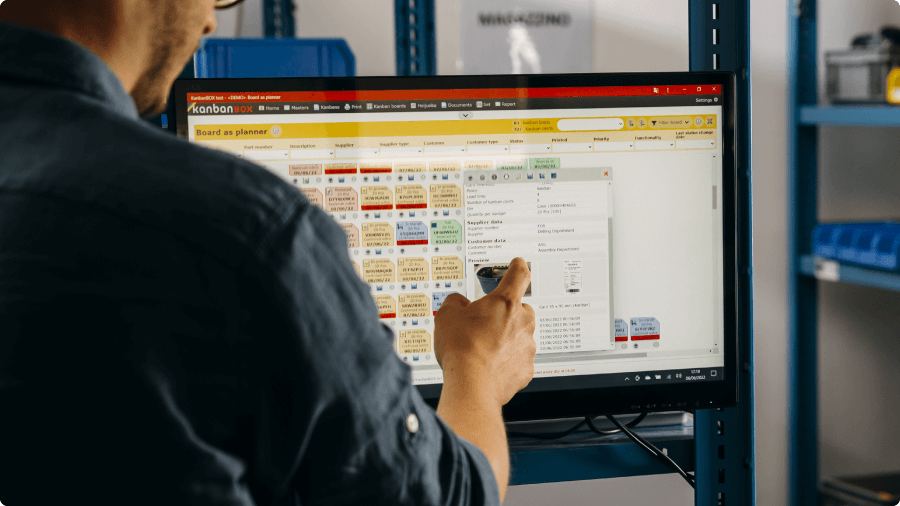

- Collect and visualize all information about kanban processes, flows and cards in one place: a digital dashboard accessible via PC, tablet or screen

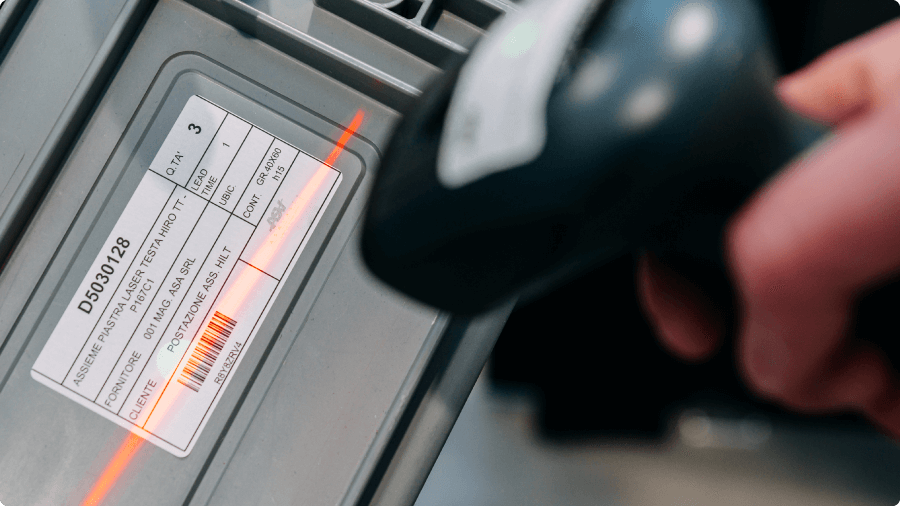

- Replace the physical collection and delivery of kanban cards with simple scanning of barcodes (placed on the kanban cards). The replenishment request will be displayed on the digital dashboard of the supplier

- Obtain important advantages that improve the production flows.

The main benefits of e-kanban manufacturing system

1. Elimination of low value activities for kanban cards’ management

With traditional kanban, replenishment signals rely on physical cards that must be manually collected, delivered and processed. E-kanban eliminates these activities by digitally transmitting replenishment signals to the system with a simple scanning. This reduces delays, loss of kanban cards and operators’ movements from the working cells to the physical kanban boards (replaced by the digital one).

2. Seamless external supplier integration for shorter lead times

Unlike traditional kanban, which often requires manual communication with suppliers, e-kanban systems automatically notify suppliers when stock needs replenishing and place pre-authorized orders. This fosters better supplier collaboration, shortens lead times, and improves overall supply chain efficiency.

3. Better visibility on processes and data

An e-kanban system provides real-time data, enabling manufacturing companies to monitor production flows, material status, inventory levels, workloads, possible bottlenecks (before they become critical issues), demand trends.

All data is available in a real-time digital dashboard, ensuring operators always work with the latest updates and inventory levels are constantly accurate, reducing the risk of stockouts and overstocking.

4. Automated optimal kanban sizing calculation

By leveraging automation and analytics, e-kanban systems provide data-driven suggestions about the optimal kanban sizing for each SKU, ensuring that replenishment quantities always align with the latest production needs. Instead of relying on manual calculations, the system continuously tracks real-time consumption data and lead times. Using this data, it suggests the optimal number of kanban cards required to maintain a steady production flow, preventing stockouts while minimizing excess inventory.

5. Production processes optimization with advanced functionalities

Some advanced e-kanban manufacturing software, like KanbanBOX, offer additional features to further optimize production processes. Functionalities such as the Sequencer, that assigns each operator/machine a precise order of processing of kanban cards in order to achieve an optimal production flow. Or the Heijunka function for demand leveling, preventing sudden spikes in production and ensuring a balanced workflow that enhances efficiency and resource utilization.

Transitioning from traditional kanban to e-kanban

For companies already using a traditional kanban system, the transition to e-kanban is straightforward. Since the fundamental process is already in place (the kanban method), the implementation doesn’t require any disruption to workflows and the transition can happen gradually: the company can begin with just few components and progressively extends it to other materials or processes, like purchasing or move processes.

Thanks to this flexibility, companies can easily upgrade to an e-kanban manufacturing system that benefits from greater operational efficiency, reduced waste, and enhanced collaboration.

Are you a manufacturing company interested in the benefits of an e-kanban manufacturing system? Learn more on our blog or contact our experts to unlock the full potential of your kanban system!

Before contacting our experts, do you want to learn more about the advantages of Electronic Kanban?

Download our Guide