E-kanban Software: what it is, what it does and key features

By Matteo Biagini

E-kanban software: what it is?

E-kanban software is a digital tool designed to implement an electronic kanban system within a manufacturing or commercial company. Its goal is to automate and simplify material replenishment management, ensuring that each component is restocked only when truly needed, according to the pull logic.

Depending on the company’s needs, e-kanban software can be used in different logistics phases:

- Procurement: for reordering materials from external suppliers

- Movement: to manage internal material transfers between departments or warehouses

- Production: to organize production flows, even multi-process or multi-site, ensuring that the line operator always has the right components at the right time

- Sales or distribution: for managing product/component delivery to customers or other facilities

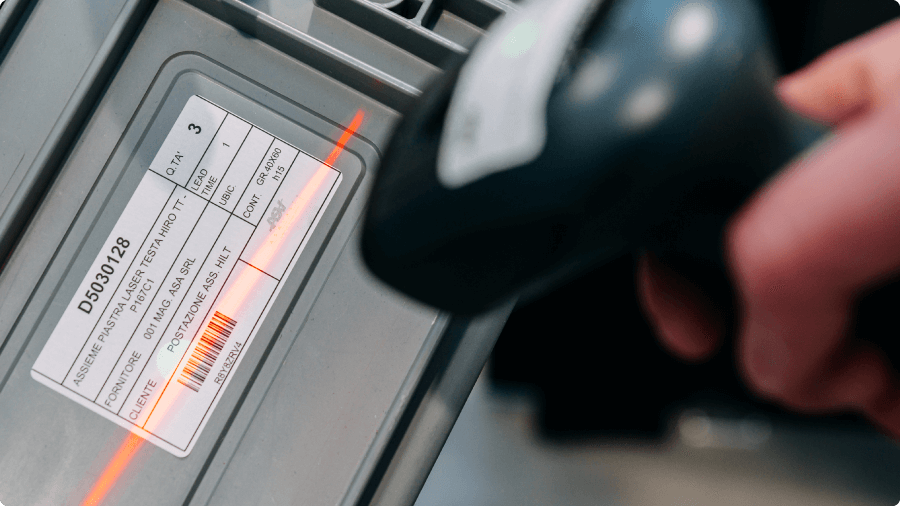

By integrating the software with common technologies (barcode scanners, kanban card printers, and internet-connected screens/PCs), the system enables smoother, more traceable replenishment flows that can be integrated with the company’s overall information system.

What an e-kanban software does?

A good e-kanban software solution allows you to:

- Generate real-time replenishment orders based on actual consumption. The order is triggered as soon as the operator scans the barcode on the kanban card attached to an empty container.

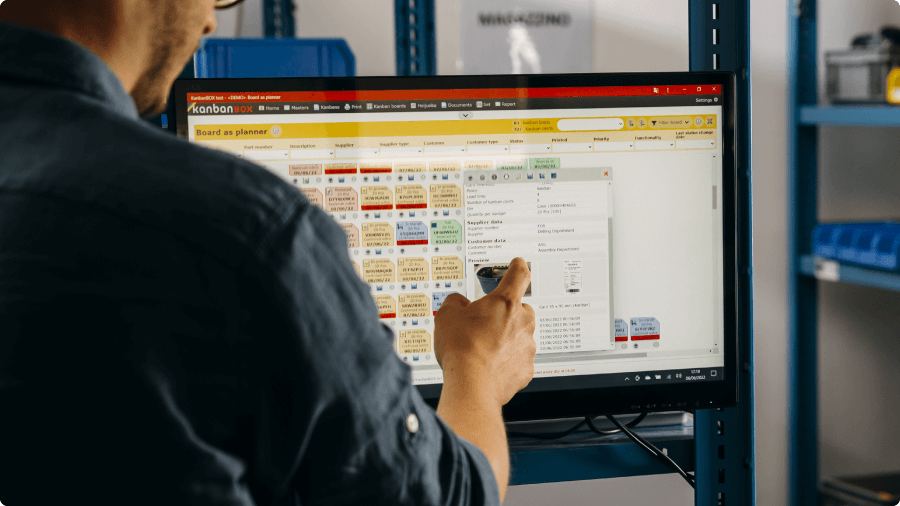

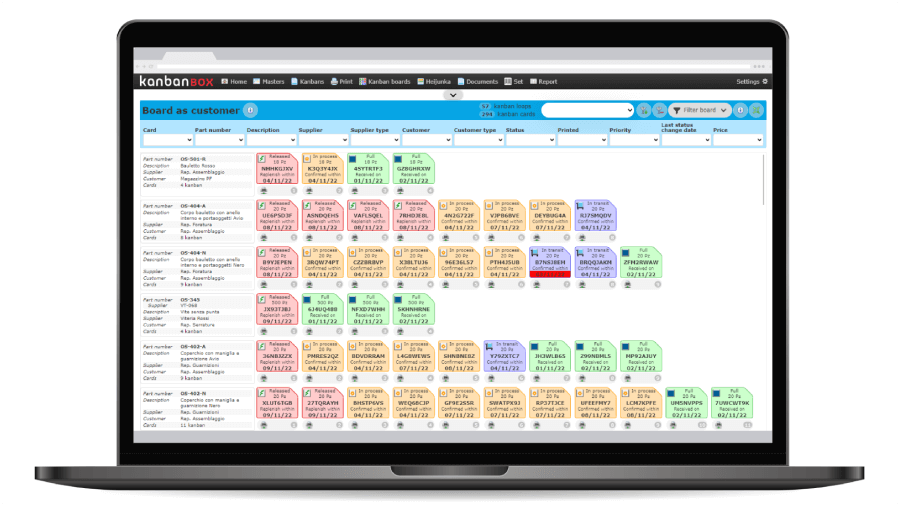

- Monitor inventory levels, consumption, and orders using a constantly updated digital board that tracks and analyzes relevant data

- Automate order and information exchange between departments, suppliers, warehouses, and customers

- Provide data and suggestions for the ideal sizing of kanban cards, based on automatic data collection

- Integrate with ERP, MES, and WMS software for a shared, scalable, and connected management system

All of this reduces errors, streamlines operations, and provides full visibility across the supply chain.

An e-kanban software is not for project management

One of the most common misunderstandings is confusing e-kanban software with tools like Trello or Asana. These apps are project management software, not e-kanban tools. The confusion arises because these platforms feature dashboards inspired by kanban boards, but they have nothing to do with the operational management of physical materials.

You can find out more in this article: What is kanban, meanings and use cases.

True e-kanban software is used in industrial settings (both manufacturing and commercial) to efficiently manage material replenishment, reduce inventory, and synchronize production and logistics flows. Some advanced e-kanban solutions, such as KanbanBOX, also include features to support workflow planning (such as a Sequencer), but their main focus remains on supply chain and production optimization, not project management.

KanbanBOX: the first e-kanban software in Europe

KanbanBOX was launched in 2010 as the first e-kanban software in Europe, with the aim of digitizing material flows managed with kanban. Over time, it evolved into a complete solution for pull-based material management throughout the entire supply chain.

Some of its most appreciated advanced features include:

- Sequencer: organizes production sequences between cells and machines based on priorities and availability, improving operational efficiency

- Heijunka: levels production to reduce fluctuations and ensure a constant production flow

- Make to Order: efficiently manages custom production according to specific customer requirements

- Milk Run: optimizes internal and external supply routes, reducing lead times and logistics costs

- Technical Drawings: integrates technical documentation directly into kanban cards, facilitating access to critical information

- Multiprocess: manages complex production flows across multiple departments or facilities, ensuring coordination and traceability

- Integration with suppliers, customers, subcontractors, and partners: shares real-time kanban data across all stakeholders via a centralized platform (including supplier negotiations), improving coordination, transparency, and delivery reliability

Today, KanbanBOX is used by over 2,600 plants in more than 35 countries, supporting the needs of SMEs, global industrial groups, and Lean consultants aiming to implement effective and scalable pull systems.

Learn more

To discover how KanbanBOX can help you reach your goals, you can:

- Follow us on LinkedIn

Download the E-Kanban Guide

Do you want to learn more about the topic? Download our E-Kanban Guide with clear and concise explanations, diagrams and processes explained step by step.

To download the Guide which explains what it is, how it works and what are the advantages of e-kanban compared to traditional Kanban, visit this page.