Interview with Dino Falciola and Massimiliano Uberti from Oleodinamica Marchesini

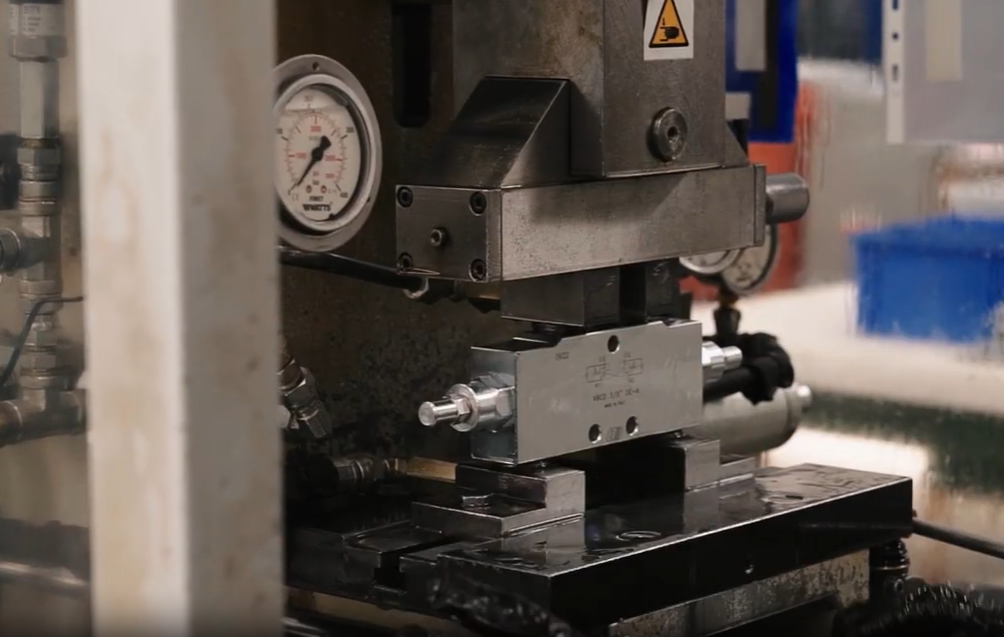

Oleodinamica Marchesini, an Italian company and part of OM Group, with over 40 years of experience in the production of hydraulic components, has undertaken a significant Lean improvement journey over the years, achieving results that, at the beginning of their path, seemed out of reach.

This transformation was made possible thanks to the work of two key figures within Oleodinamica Marchesini: Dino Falciola (CEO) and Massimiliano Uberti (IT Manager).

In this interview, Dino and Massimiliano share the Lean transformation journey of Oleodinamica Marchesini and how, in just a few months, they managed to shift from Make to Stock to Make to Order production.

Dino, before adopting KanbanBOX, what was the company’s level of Lean knowledge?

A few years ago, we had started promoting a Lean mindset within the company, understood as a set of practices aimed at actively involving people to identify and eliminate all muda [Japanese for “waste”], meaning non-value-added activities.

We invested in training, both by personally sharing my experience and results-driven approach, and by organizing specific Lean courses for around fifteen employees.

Beyond that, we had implemented a manual kanban system in production, using magnetic tags and kanban boards. The system worked well and had already helped us reduce warehouse stock.

What led you to look for other solutions?

The fact that the system in place was no longer helping us meet our business goals or refine the system further. Our main objective was to further reduce lead time, which was already good, by eliminating waste and drastically reducing inventory: for us, this was a pressing need.

The manual kanban had helped us achieve a good level, but it couldn’t take us any further. For example, this is the 28th consecutive month we’ve been reducing stock, but in the three months before adopting KanbanBOX, we hit a plateau, like we’d reached the ceiling of the model.

There were several reasons for this stagnation, including the fact that the kanban card was not linked to a single box, but to a layer of pallets, about 12 boxes. This approach was useful for visually managing stock and suitable for some item codes, but for others it generated oversized orders and excessive inventory volumes.

The second major limitation was the inability to link different steps in multiprocess production flows, like laser marking, which operated under different rules.

As a result, our production management was essentially Make to Stock, and only slightly pull-based [driven by actual demand].

Massimiliano, how did you find the right solution to your needs?

We conducted a software selection process by researching information online. Among the various resources, I came across a video interview with Mec-Track (Read the Meck-Track case study here), where the company talked about their production management challenges and how they solved them using KanbanBOX.

There were many similarities with our situation, particularly regarding multiprocess workflows. From there, we got in touch with KanbanBOX and met Miriam, who would become our point of contact and answered all our questions. Our first impression was excellent, both in terms of the software’s functionality and the people behind it. That impression was confirmed when they visited our facility and conducted a Value Stream Mapping of our flows.

Massimiliano, as the IT manager, what were your thoughts on adopting external software?

As an opportunity. We’re a business-oriented company, and we see IT as a service function: if we identify a tool that can improve business performance, it’s our job to support and enable the change. And that’s exactly what we did.

Of course, we first verified that it met all technical requirements, including ISO 27001 certification for information security, which is a key criterion when selecting software vendors. Also, at a trade show, I happened to meet the IT manager from Mec-Track, the one from the interview, and he confirmed the reliability of the platform.

Another important aspect was the possibility to integrate the software with our ERP, so that orders created in the ERP would automatically generate production kanban cards in KanbanBOX, effectively activating the entire order processing flow.

Dino, what other requirements did the solution need to meet?

Ease of use, a user-friendly interface, and the ability to easily manage kanban sizing and maintenance.

The solution met all our needs, so we chose it and started exploring it. Plus, the pricing model, based on a monthly subscription that’s modular and flexible depending on the features used, was a perfect fit for us.

Did the modular monthly pricing structure reassure you?

Yes, it gave us confidence because we absolutely didn’t want to end up in a lock-in situation, where you feel forced to use software just because of a large upfront investment in annual fees and implementation costs.

With KanbanBOX, the initial investment was reasonable, while the modular monthly pricing, which scales with actual software usage, turned out to be perfectly aligned with our business needs. As we explored more of KanbanBOX, we discovered new features that allowed us to use the software far more than we initially planned. The cost increased, yes, but the benefits far outweighed it. The value we gained was exponentially higher.

Massimiliano, what can you tell us about the KanbanBOX implementation process at Oleodinamica Marchesini?

The implementation phase was fast and lean. What helped was the great relationship we had with the KanbanBOX team, who came on-site to install the software and train our operators on how to use it.

But what truly made the difference was our drive to move forward. Throughout the different phases of implementation, we always set ambitious internal goals for the number of items, processes, and flows to integrate with the new system. We achieved them step by step, with what we called “courteous urgency”. Once the first results were in, we hit the accelerator. In just a month and a half, we rolled out the software to all high-rotation items. Then we extended its use to other codes, like low-rotation items, set up the ERP integration, implemented multiprocess kanbans, and finally discovered the benefits of Synchro orders [for managing closed-loop orders].

Those Synchro orders in particular allowed us to rethink certain aspects and define workflows that would have been unimaginable just six months earlier. We shifted from Make to Stock to a Make to Order or Assemble to Order model.

When I think about how far we’ve come in such a short time, I can’t help but smile. Of course, our ambitious goals keep us moving forward, but every now and then I stop and say to Dino: “Look at what we’ve done, look at the progress we’ve made, look at these results!”

Dino, do you agree that Synchro orders were the turning point?

Yes! Synchro orders are a feature we explored later on, but they turned out to be essential to getting where we are today.

At first, we used them to manage occasional orders in a pull logic. Then we realized we could apply them to many other materials, accelerating the transition to an almost pure Make to Order model.

The interesting part is that this wasn’t our original goal, we started with the idea of digitizing our kanban flows, but as we discovered the software’s potential, we realized we could go much further, toward a fully demand-driven production system… and that’s exactly what we did.

And the results speak for themselves: when we had the manual kanban, we managed our highest-rotation item with 12 pallets of 50 boxes, about 600 boxes. With KanbanBOX, I thought we might get down to 200 boxes. So you can imagine my satisfaction when we went well below that: first to 93, then to 14. Soon we’ll be down to just 2 boxes.

We’re producing the same amount as before, but now the hundreds of other boxes are shipped directly to customers as soon as they’re assembled, completely or almost completely eliminating storage.

The only regret I have since adopting the software is not having taken pictures of the warehouse six months ago, because it’s totally different now.

Are you satisfied with the results from adopting the software?

Absolutely. We’ve reduced lead time by a full 7 working days, even though it was already good. We used to deliver within a maximum of 3 weeks.

We’ve reduced stock value by €1 million, space that used to be dedicated to just our top-selling item now hosts about half of our total revenue.

We’ve increased annual inventory turnover by +1.5, with a target of 8 turns by the end of the year, 10 by the end of Q1 next year, and 12 in the medium term.

You see, before KanbanBOX, we were already committed to Lean improvement, but we lacked the tools to fully unlock our potential. Now we have an enabling tool in our hands that lets us fully unleash it.

It was like the company was a bottle of Champagne ready to pop, just held back by the wire cage. KanbanBOX was what removed that cage, finally letting the cork pop and releasing all the energy of our organization.

How did production operators respond to the software’s introduction?

Positively. because they understood it was another step forward in our continuous improvement journey, which began years ago with manual kanban. So we didn’t face any resistance.

In fact, the new way of working brought important changes that benefited the operators directly, such as the near-elimination of picking activities.

Some time ago, before we had adopted KanbanBOX for managing low-rotation items, the person in charge of that department stopped me and asked, “So when are we starting with this tool in our area too?” That’s when I realized it was something the operators wanted to implement. I replied, “Okay, let’s go live with the low-rotation items too.”

Massimiliano, did you get the same impression?

Yes, the transition to KanbanBOX was seen as a benefit. as a system that improved the way of working. And the results confirmed that impression.

I think if I had to tell them today that we’re going back to manual kanban, they’d go on strike!

Read more

If you haven't already, read the full Oleodinamica Marchesini case study