Supplier Collaboration make Easier

Simplify, Accelerate, and Automate Procurement Negotiations

KanbanBOX is not just a tool for managing your pull material replenishment system, it’s also a powerful solution to handle the growing complexity of modern supplier collaboration. As global supply chains become more dynamic, managing suppliers effectively has become a key challenge for building flexible, responsive operations.

With the Supplier Collaboration features in KanbanBOX, you can:

- Reduce procurement time and costs by increasing transparency and sharing real-time data with suppliers

- Manage negotiations in real time, in a secure and authorized way, avoiding miscommunications and enabling mutually beneficial agreements

- Build trust and stronger supplier relationships, leveraging digital tools to prevent disruptions and increase supply performance

A More Efficient Procurement Process with KanbanBOX

Flexible

Manage negotiations with all your suppliers from a single board, for any type of order: Kanban orders, Standard purchase orders (POs), Production work orders (WOs)

Collaborative

Say goodbye to endless email threads. Both you and your suppliers can submit, approve, or edit order proposals directly on the platform, in just a few clicks.

Optimized

By automating procurement tasks and standardizing processes, KanbanBOX helps you accelerate supply cycles, eliminate waste, and reduce non-value-added activities.

KanbanBOX Boosts Supplier Collaboration

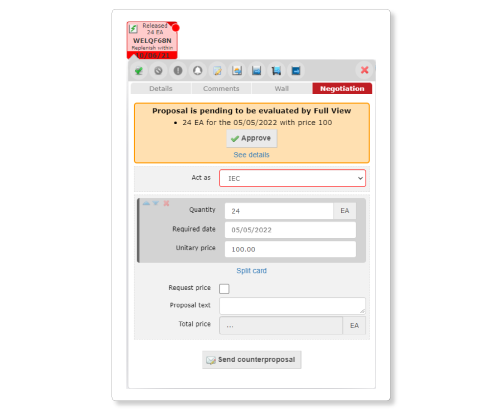

Negotiate with Clarity and in Real Time

KanbanBOX gives you all the tools you need to establish strong and agile supplier collaboration:

- Define key info such as quantity, unit, price, and delivery date

- Respond to proposals, send reminders, approve or reject requests with one click

- Monitor the full order lifecycle in real time

All managed through a dedicated workflow synced with your ERP.

Generate Documents Automatically

With the Supplier Collaboration features you can:

- Automatically create and send delivery notes and shipping documents (inbound and outbound), complete with all order details

- Streamline receiving and quality control processes by reading unique material barcodes

- Attach supporting documents such as technical drawings and quality standards

Both physical flows and information flows are fully tracked and synchronized, keeping everything you need at your fingertips.

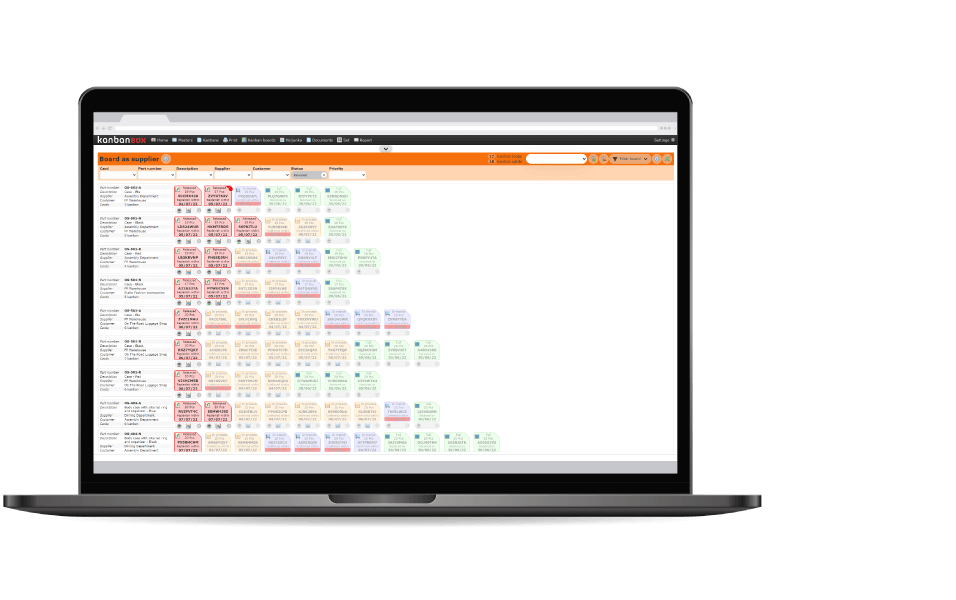

One Dashboard for Everything

An electronic dashboard gives you full visibility into order types, statuses, and any alerts or pending actions.

- Each order is tagged with a unique kanban card

- Visual indicators help identify the required action

- Click any card to open the negotiation interface

This makes the supplier collaboration and negotiation process faster, more responsive, and more transparent, for both sides.

Integrate with Your ERP

KanbanBOX connects easily with any ERP system, allowing real-time, automated updates of purchasing and inventory data.

Learn moreExchange Data in Real Time

With KanbanBOX, you can share up-to-date information with your suppliers instantly, saving time and always staying aligned.

Watch how it worksKanban-Based Purchasing

By managing material replenishment through purchase-kanban, you can cut inventory costs, and reduce order management time.

Discover moreReferences

Some of our clients

Case studies

Sacchi | Electrical Supply Distribution

Sacchi uses KanbanBOX to offer its customers a kanban-based sales service, ideal for recurring supplies and supports long-term customer loyalty

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, then integrated it with its own ERP, with Oracle Sequencer and with suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector