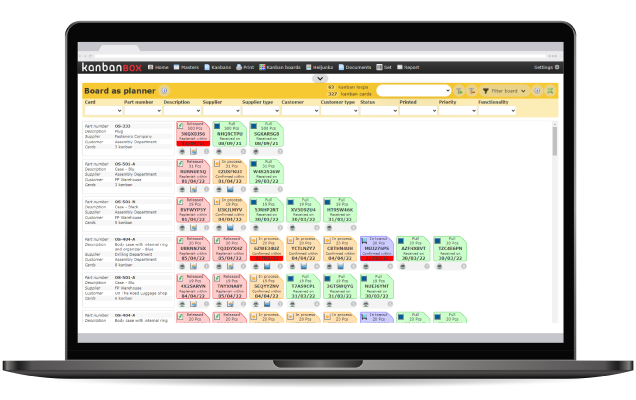

KanbanBOX for Make to Order Planning

One Platform for All Your Procurement Flows, even Beyond Kanban

For many companies, efficiently handling Make to Order (MTO) processes is a daily challenge. In this approach, production only begins after receiving a customer’s specific order, which adds significant complexity.

The situation becomes even more complicated when companies operate with a mix of Make to Order and Kanban orders, often relying on different tools and systems to manage each. This leads to fragmented processes, duplicated data, and coordination issues between internal departments and external suppliers.

But everything changes once you discover that KanbanBOX allows you to manage both Kanban and Make to Order orders seamlessly, on the same platform, with all the operational advantages of simplicity, visibility, and responsiveness.

Managing Make to Order Orders with KanbanBOX

Whether your company operates entirely on a Make to Order basis or in combination with Kanban, KanbanBOX enables you to manage MTO workflows in a structured, efficient, and fully digital way.

Here are the key benefits:

- Instant visibility into order status via a clear and intuitive digital board

- Real-time transmission of orders and updates to suppliers, customers, and subcontractors

- Ability to attach important documents such as technical drawings, specifications, and special instructions

- Direct communication on the order card, minimizing the need for emails and external messaging tools

- Full traceability of every step and interaction throughout the order lifecycle, ensuring maximum transparency and control

A concrete example is Robopac, a global leader in packaging machinery, which uses KanbanBOX across multiple plants, including one dedicated to the production of customized machines. In that facility, component management is handled entirely through Make to Order orders, fully leveraging the capabilities of the platform.

One Platform for Both Make to Order and Kanban Orders

Bringing Kanban and Make to Order flows together on a single platform is a major strategic advantage for modern manufacturing organizations. Here’s why:

- Consistent workflows and standardized processes

By applying a unified operational logic across both pull-based replenishment and MTO production, you reduce organizational complexity. You work within a single shared workflow, eliminating parallel systems, duplicated data, and tool confusion. - Maximum visibility and control

With all activities shown in one integrated digital board, you can monitor the real-time status of every order, regardless of the production logic. This leads to faster decision-making, easier identification of bottlenecks, and smoother collaboration across the supply chain. - Greater operational efficiency

Standardizing pull processes helps cut setup times, shorten learning curves, eliminate non-value-added tasks, and reduce the costs associated with maintaining multiple systems. Your teams can focus on high-value work instead of manual data entry or reconciling information, especially thanks to KanbanBOX’s integration with your ERP system.

Manage Production with KanbanBOX

Use KanbanBOX to build a flexible, responsive production system that can handle demand volatility and meet customer needs faster.

Go to the pageKanbanBOX and ERP Integration

KanbanBOX integrates seamlessly with your existing ERP system, allowing for automatic entry of both Kanban and Make to Order orders, ensuring centralized, streamlined flow management.

Learn moreKanbanBOX: More Than Just e-Kanban

Beyond its powerful e-kanban features, KanbanBOX is a complete pull-based supply chain platform, supporting closed orders, make to order processes, and supplier collaboration from end to end.

Discover moreReferences

Case studies

Sacchi | Electrical Supply Distribution

Sacchi uses KanbanBOX to offer its customers a kanban-based sales service, ideal for recurring supplies and supports long-term customer loyalty

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, then integrated it with its own ERP, with Oracle Sequencer and with suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector