Milk Run to optimize the picking process

KanbanBOX's Lean functionality to optimize material collection and delivery routes

Milk Run is a supply management strategy that involves the sequential collection of various materials from different suppliers—or, in the case of internal logistics, from different warehouse areas, in a single, planned route.

This approach helps optimize time and resources by:

- Creating a more efficient supply flow

- Reducing waste in warehouse-to-line movements

- Enabling lean and intelligent replenishment management

With KanbanBOX, you can configure both internal and external milk runs, optimizing collection and delivery routes, reducing lead times, and increasing overall logistics efficiency.

Tailored Replenishment

Fully aligned with kanban logic, KanbanBOX ensures that replenishment activities are targeted to actual needs, delivering only what’s needed, when it’s needed.

Sequential Collection

No more random picking: the milk run enables standardized and optimized picking routes, significantly reducing wasted time and unnecessary movement.

Reduced Lead Times

Implementing a milk run makes your supply chain more fluid, cutting picking times as well as production downtime due to delayed replenishment.

What is it and what does “Milk Run” Mean?

The milk run is a logistics strategy based on a predefined sequence for collecting and delivering materials. The term comes from the traditional “milk delivery” system, where delivery workers followed a fixed route to deliver milk to homes and collect empty bottles.

Similarly, KanbanBOX’s dedicated functionality guides warehouse workers along a standardized, pre-planned picking route, defined in advance based on a list of all components that need to be replenished across different workstations.

- An internal milk run refers to routes within the company, between the warehouse and production lines (using movement kanban)

- An external milk run involves suppliers or external plants for picking up and delivering materials

In short, it’s a standardized, efficient method for meeting supply needs clearly and precisely, while optimizing time and resources.

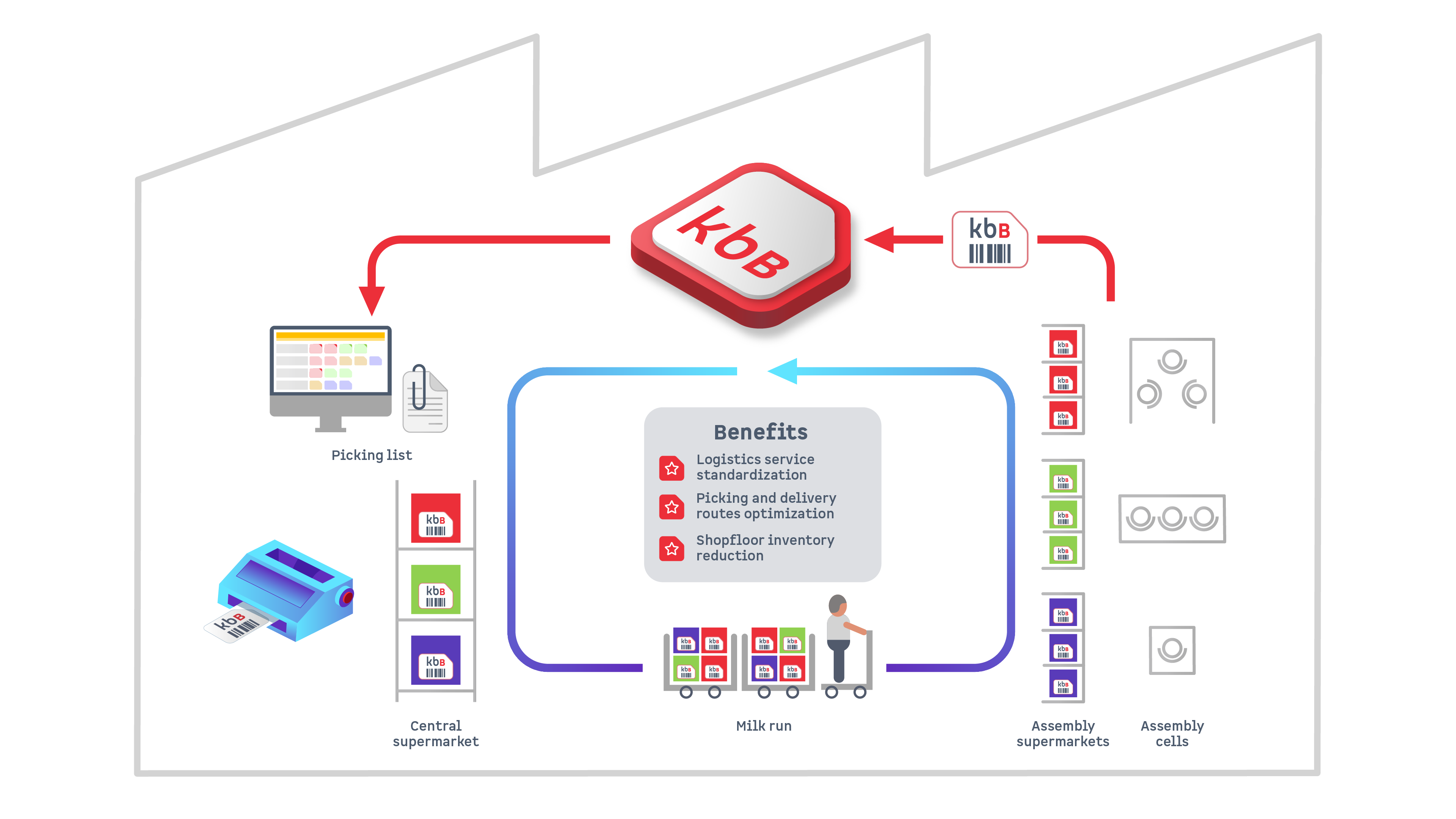

Optimize Your Internal Milk Run with KanbanBOX

KanbanBOX makes it easy to manage internal milk runs in a structured and efficient way. Kanban cards for materials to be replenished and picked are grouped and sorted in the optimal picking order, guiding warehouse operators along the shortest possible route and minimizing non-value-added movements.

If you’re using logistics trains, KanbanBOX takes their size and load capacity into account to optimize the picking list based on real operational constraints. The result is significantly better replenishment performance, more punctual internal deliveries, and a smoother logistics flow aligned with production needs.

With KanbanBOX, an internal milk run allows you to:

- Standardize internal logistics and picking activities while reducing line-side stock

- Optimize picking and delivery routes by generating pull-based picking lists

- Deliver to each workstation only what is needed, when it’s needed

Manage External Milk Runs in an Integrated Way

With KanbanBOX, managing external milk runs becomes simpler, more efficient, and more collaborative. Once a supplier has prepared the material and marks it as “Available” on the platform, the client can instantly see which materials are ready to be picked up. Using the system’s picking list, the company knows exactly which suppliers to visit and what to collect, enabling precise planning of the logistics rounds.

This method allows you to streamline supply flows, eliminate unnecessary movements, and optimize truck loading. The result: increased logistics productivity, fewer delivery delays, and a lower risk of stockouts. Logistics becomes easier, costs decrease, and the partnership between customer and supplier is strengthened through transparent, real-time collaboration.

Better Results with Less Effort

- Simplified logistics management

- Optimized procurement flows

- Increased production flexibility

Reduce logistics costs

- Lower operational and inventory costs

- Reduced transport and logistics costs

- Better truckload efficiency (small lots are easier to organize and consolidate)

Save Routes, Save Time

- Shorter delivery cycles

- Fewer resources needed for transportation planning

- More time and people focused on value-added activities

Do you have any questions about this or other features?

Case studies

Sacchi | Electrical Supply Distribution

Sacchi uses KanbanBOX to offer its customers a kanban-based sales service, ideal for recurring supplies and supports long-term customer loyalty

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, then integrated it with its own ERP, with Oracle Sequencer and with suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector

References

Some of our clients