KanbanBOX for Industry 4.0

Digitize your production processes with a Smart Factory approach

In today’s industrial landscape, companies are facing increasingly complex challenges: constantly evolving markets, growing demand for product customization, the need for speed, and seamless digital connections between people, machines, and systems.

KanbanBOX, designed to support companies in the pull management of replenishment activities, meets these challenges by offering a complete platform for the digital and automated management of material flows according to the principles of Industry 4.0.

With its electronic kanban system (e-kanban) and ability to integrate with machines, ERPs, and factory technologies, KanbanBOX helps transform production processes into connected, lean, and responsive systems, enabling companies to increase efficiency, traceability, and collaboration throughout the entire value chain.

Digitalization

KanbanBOX digitizes production process information, making your production and replenishment system traceable, measurable, and connected

Integration

Through Internet of Things (IoT) logic, KanbanBOX automatically communicates with machines, ERPs, WMSs, and production systems

Traceability

KanbanBOX automatically tracks data, allowing you to analyze and transform it into strategic and operational insights

Digitalization within everyone’s reach

Unlike in the past, digital transformation is no longer a luxury for large enterprises. It is now a growth opportunity for all companies, including SMEs.

Digitizing production and commercial processes means gaining greater process visibility, production flexibility, and continuous connectivity between people, departments, and suppliers, regardless of company size.

With KanbanBOX, this opportunity becomes concrete and accessible. Thanks to its modular and scalable pricing model, every company can start its digitalization journey gradually, based on current needs, and expand over time, improving productivity, efficiency, and competitiveness without unnecessary costs or large investments.

Automate processes

with an Industry 4.0 approach

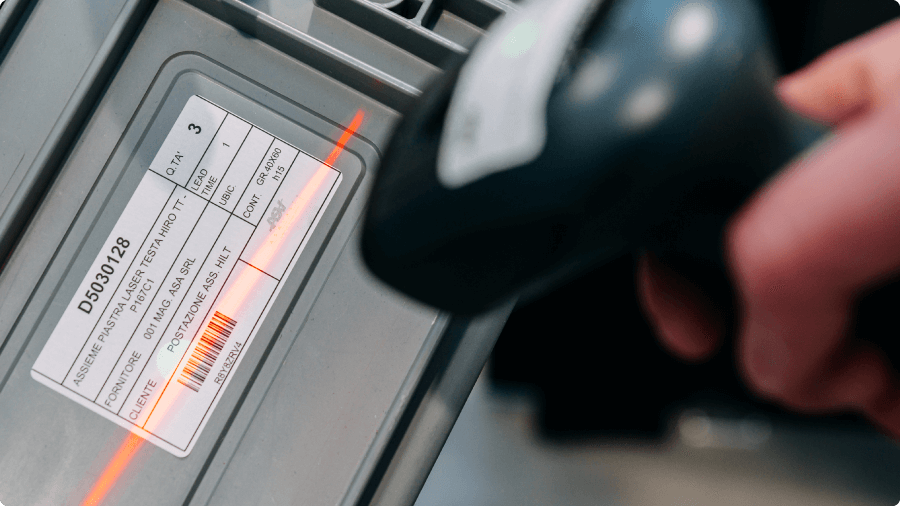

Taking up the challenges of the digital revolution that is underway and Industry 4.0, KanbanBOX is equipped with tools and solutions that combine the smart technology of an electronic kanban (e-kanban) with systems to automate the flow of materials.

Thanks to the interconnection of machinery allowed by the IoT, KanbanBOX is able to communicate with the work centres and the various company production resources according to 4.0 logic. The result: higher productivity and higher efficiency.

KanbanBOX natively allows the communication and transmission of information between central and peripheral decision makers, achieved through specific modules such as the Sequencer.

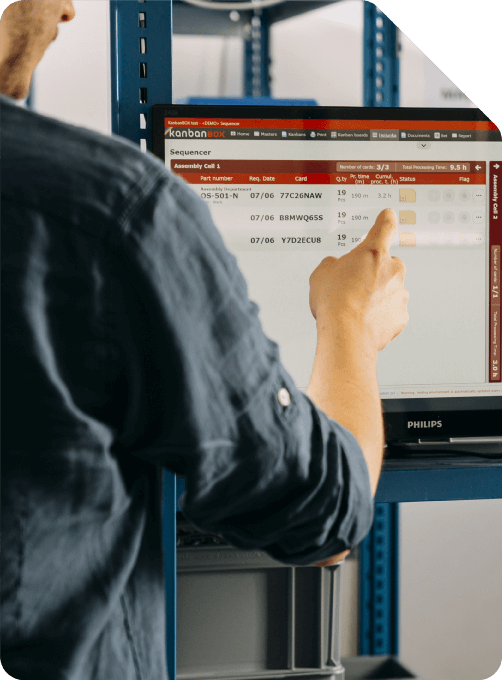

The Sequencer

To support digitalization in an Industry 4.0 context, one of KanbanBOX’s most valued tools is the Sequencer.

The Sequencer simplifies operator work through integrated connectivity and remote machine monitoring, allowing machines to automatically read and execute the assigned work order.

With the Sequencer, you can:

- Collect real-time data

- Monitor events on each individual machine or your entire machine park, configuring notifications and permissions

- Manage complex manufacturing processes, such as sheet metal processing, optimizing laser cutting, punching, or bending machines to produce component sets belonging to multiple work orders.

Thanks to its intuitive programming interface and built-in connectivity, the Sequencer simplifies even the most complex operations, saving time, material, and cost while improving workflow efficiency.

The Sequencer in detail

Want to learn how the Sequencer can simplify operator work and make your production more efficient and connected?

Visit the dedicated page to explore this popular KanbanBOX feature, appreciated for its ease of use and fast results, or contact us to speak with one of our specialists.

Industry 4.0 and ERP integration

One of the key pillars of Industry 4.0 is the interconnection between systems, people, and machines. In this context, integrating KanbanBOX with your ERP becomes essential to turn digitalization into real operational value.

Learn more about KanbanBOX’s flexible ERP and software integration options on the dedicated page.

Go to ERP IntegrationDo you have any questions?

Case studies

Sacchi | Electrical Supply Distribution

Sacchi uses KanbanBOX to offer its customers a kanban-based sales service, ideal for recurring supplies and supports long-term customer loyalty

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, then integrated it with its own ERP, with Oracle Sequencer and with suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector

References