Heijunka for Production Leveling

The Lean KanbanBOX Feature for Just-In-Time Manufacturing

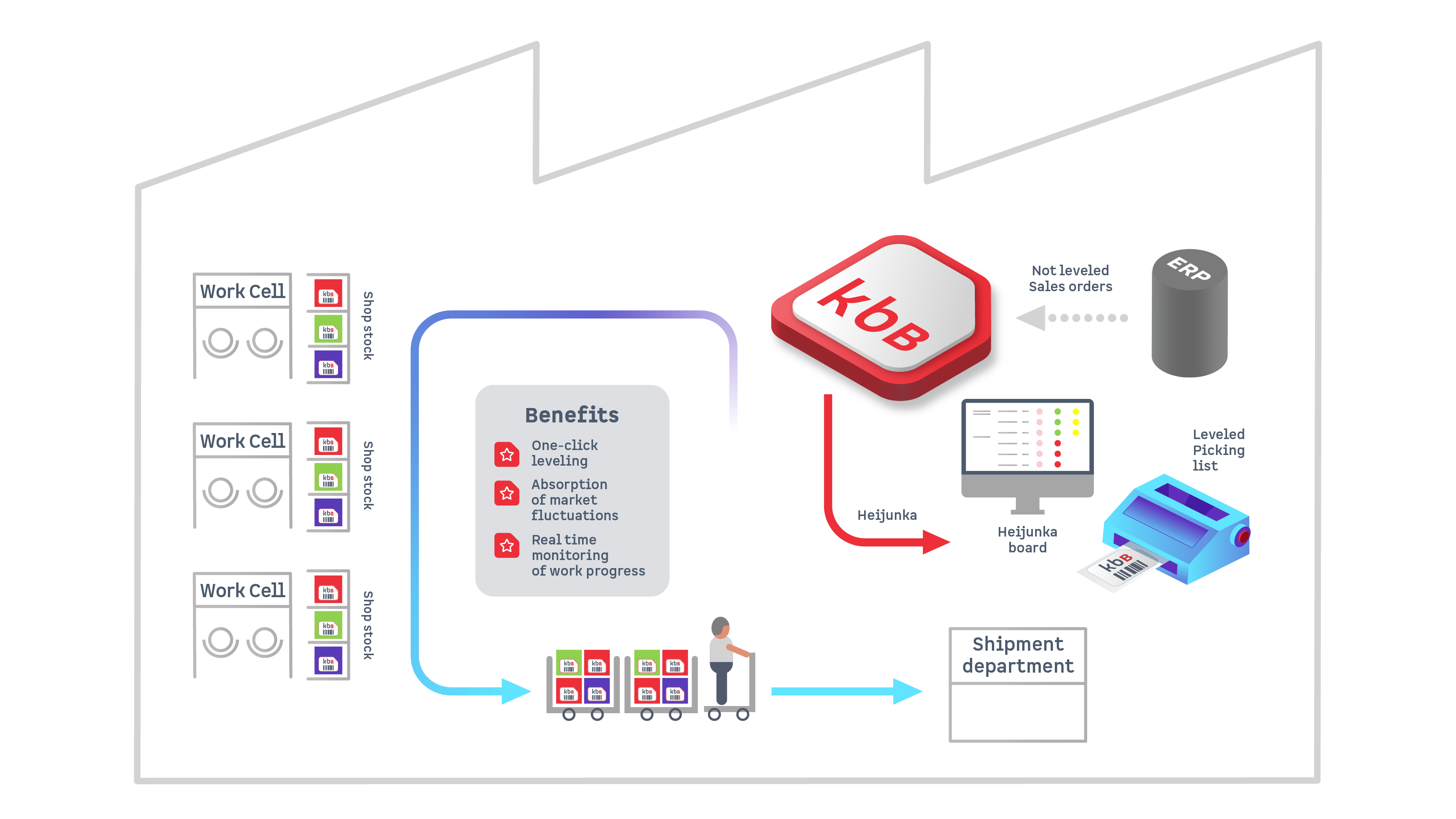

Heijunka is a Lean tool for production leveling that balances the workload across production cells while minimizing supply fluctuations. It’s an essential method for managing demand peaks and moving closer to true Just-In-Time production.

With this dedicated KanbanBOX feature, work orders are released in small, regular batches, creating a consistent production rhythm. After all, leveling production load and aligning it with takt time (the pace of customer demand) is a core principle of any Lean manufacturing process.

The two key pillars of leveled production are:

-

Leveling the production volume

-

Leveling the product mix

The Three Steps to Apply Heijunka with KanbanBOX

Enter the Data

The first step in implementing Heijunka in KanbanBOX starts with entering the demand forecast for the time period you want to level.

Apply Leveling

The system automatically levels the production demand. The results can be manually adjusted, and you can proceed to print the kanban cards to be processed.

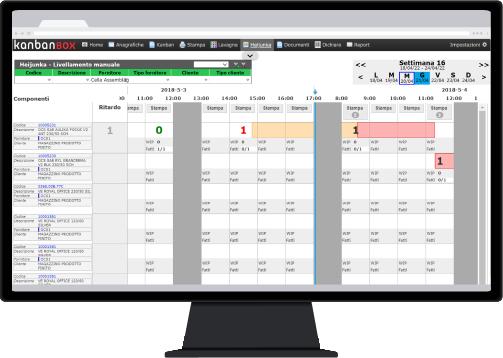

Monitor Progress

Track the kanban cards scheduled for the current pitch and check the status of the Heijunka board, including any potential delays in the dedicated monitoring section.

What You Can Do with the Heijunka Feature in KanbanBOX

With Heijunka in KanbanBOX, you can:

-

Evenly distribute the workload across the week and each workday

-

Visualize production schedules and related information clearly

-

Define a consistent production rhythm for operators

When working with a fixed number of cells or machines, the Heijunka module helps you distribute both workload and resources over time, allowing you to produce the same quantity and mix each day.

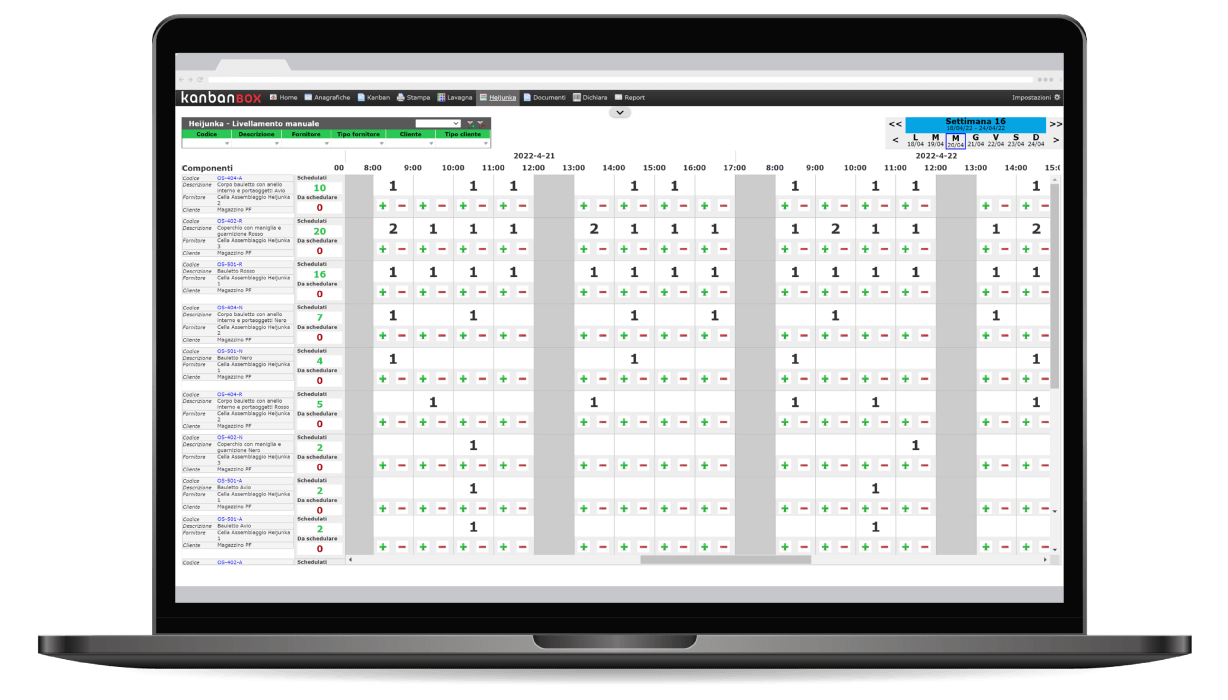

The KanbanBOX Heijunka board

The Heijunka Board in KanbanBOX gives you full control over the leveling process. You can manually adjust the system-generated production schedule whenever needed.

The built-in leveling algorithm is:

-

Customizable to suit your specific process requirements

-

Manually editable to refine the proposed schedule

-

Monitorable in real time, so you always stay up to date

Thanks to multiprocess kanban, progress on the Heijunka board can also trigger upstream processes, such as component kitting or pre-assembly, ensuring synchronization across departments.

Other Tools for Managing Unstable Production: The Sequencer

The Sequencer is another powerful KanbanBOX feature designed to handle irregular production. It allows you to plan operations and choose the best production sequences, helping your team lead manage the complexity of day-to-day production scheduling.

Learn moreSimplify Production Planning with the Sequencer

With KanbanBOX’s Sequencer feature, it’s easy to optimize production scheduling in a simple and intuitive way, allowing operators at every workstation to continue working without interruption.

Watch the videoReferences

Case studies

Sacchi | Electrical Supply Distribution

Sacchi uses KanbanBOX to offer its customers a kanban-based sales service, ideal for recurring supplies and supports long-term customer loyalty

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, then integrated it with its own ERP, with Oracle Sequencer and with suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector