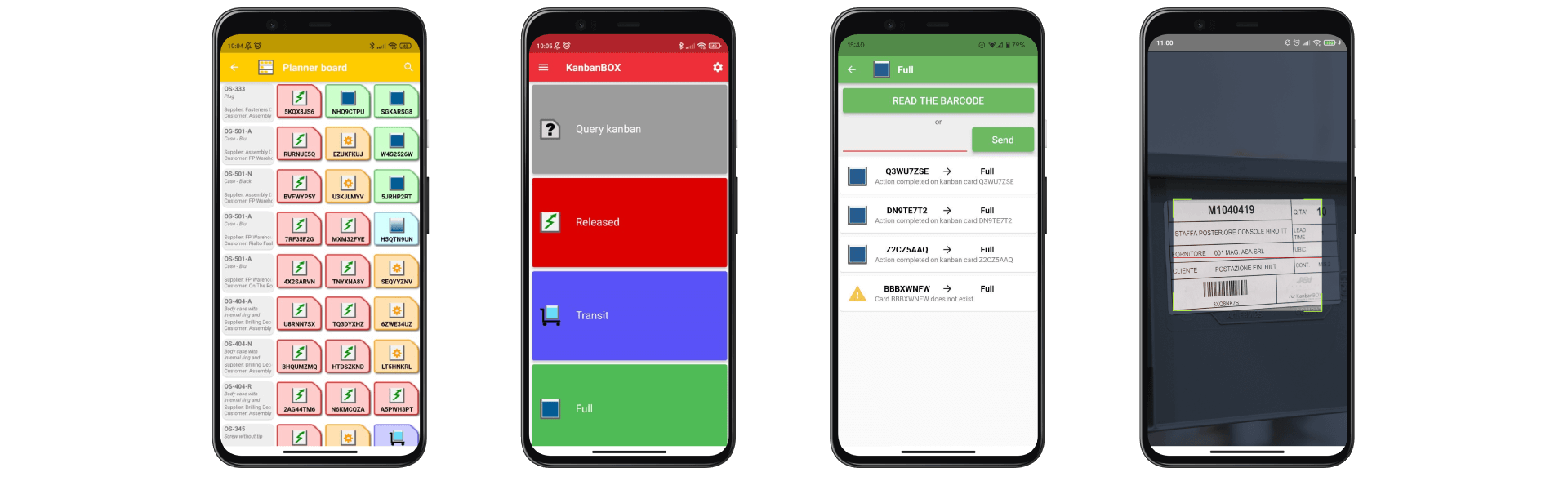

KanbanBOX App for Android and iOS devices

The app that keeps your kanban system always at your fingertips

KanbanBOX has always been a web-based software, designed to ensure maximum accessibility and usability from any connected device.

To make operators’ work even easier and faster, a dedicated mobile app is now available, specifically designed for on-line use in production environments.

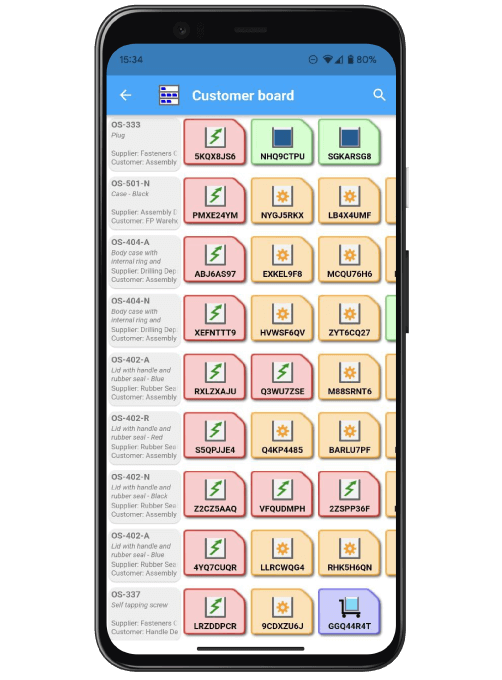

The KanbanBOX App can be installed on industrial handhelds or smartphones, allowing operators to scan kanban cards, update statuses in real time, send reminders to suppliers, and manage daily operations with just a few taps.

An intuitive and fast interface, built for production environments, that brings the full power of KanbanBOX directly to the shop floor.

Simple and intuitive

A clean and easy-to-use interface designed for everyday use on the production line. Every function is at your fingertips, with no need for lengthy training

Designed for operators

Optimized for the production environment, the KanbanBOX App simplifies operators’ daily activities on the move, starting with barcode scanning.

Always connected

Whether on handheld devices or smartphones, the app instantly synchronizes with the web platform, ensuring real-time data and complete visibility over material flow.

The right tool for working on the move

When working on the move, in the warehouse or across the production floor, it’s essential for technicians and operators to act exactly where the material is processed, without wasting time moving back and forth to fixed workstations just to enter or update data in the e-kanban system.

The KanbanBOX App was developed specifically to meet these operational needs:

- Developed and continuously updated in Italy by our in-house R&D team

- Available for both Android and iOS devices

- Easy to use, with an intuitive and customizable interface

- Over 5,000 active users worldwide

What you can do with the KanbanBOX App

- Capture e-kanban card barcodes directly using your phone’s camera or industrial devices with built-in readers

- Increase productivity and ergonomics with an intuitive technology that’s always within reach

- Access KanbanBOX data faster to make decisions more efficiently and quickly identify and resolve material flow issues

- Communicate more effectively for better team productivity and stronger process compliance

The KanbanBOX App

for Android devices

Do you have a smartphone or tablet running Android?

Click the button below to access the Google Play Store and download the app.

The KanbanBOX App

for iOS devices

If your company uses iPhones or iPads, click the button below to access the Apple App Store and download the version designed for iOS devices.

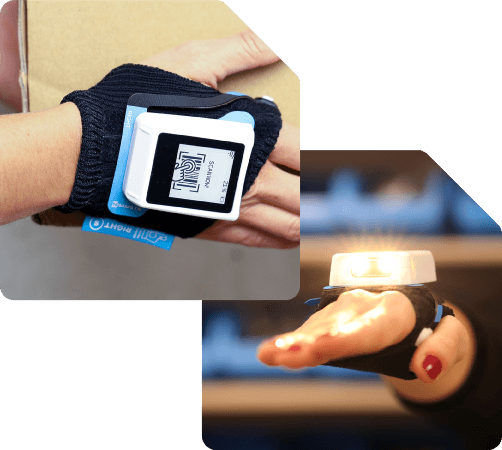

Go to the Apple StoreBeyond scanning: KanbanBOX App for wearable devices

The KanbanBOX App isn’t just a replacement for traditional barcode guns or other scanning tools: it also works with more versatile devices, such as handhelds and smartphones.

Thanks to its compatibility with wearable technologies, it can equip operators with hands-free solutions, ideal for those who need to move freely or handle complex tasks without interrupting manual work.

This makes kanban card tracking and updates smoother and more natural, improving ergonomics, speed, and safety during operations.

This evolution allows companies to bring digitalization directly into daily work, turning every movement into traceable data and every operator into an active part of the real-time information flow.

Case studies

Sacchi | Electrical Supply Distribution

Sacchi uses KanbanBOX to offer its customers a kanban-based sales service, ideal for recurring supplies and supports long-term customer loyalty

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, then integrated it with its own ERP, with Oracle Sequencer and with suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector

References