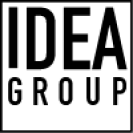

Wearable and

hand-free scanner

Wearable e-device and wearable wireless bar codes with BLE or RF technology: for hand-free ergonomic and efficient work flows

In the present day, the most efficient way to scan is the wearable. KanbanBOX integrates wearable scanners to improve workflows by making them wireless. Equipped with sensors that monitor various variables, they are used to scan the items in the warehouse quickly. And to reduce the margins of error.

A solution to speeding up the scanning of goods, not interrupting the handling of materials by operators, and making workflows smarter. With a noticeable improvement in workers’ comfort and ergonomics!

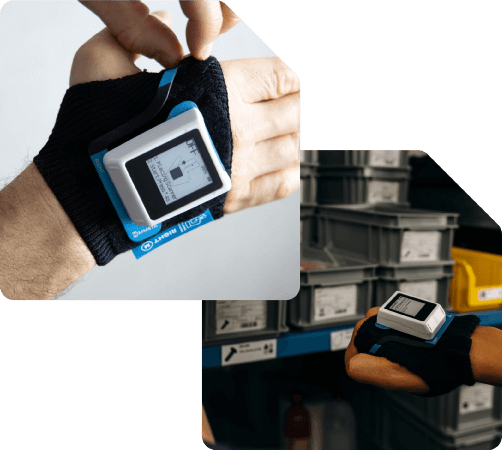

Zero errors, maximum comfort

Wearable barcode scanners are ergonomic, accurate, and fast. To work better and on the move, optimize operations and eliminate the possibility of error!

- Real-time visibility of the readings on the KanbanBOX

- Integrated navigation in the KanbanBOX menu

- Status changes and quantity variations

- Device-free picking and recovery.

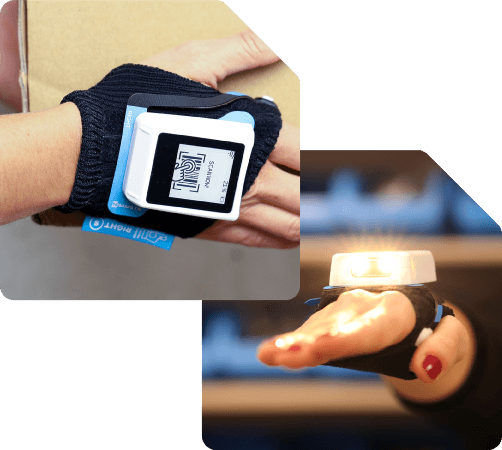

Imediate accessibility

and user-friendly

Wearable readers ensure a lightweight design and are comfortable to wear even for long periods. We also ensure:

- Quick connection via QR Code from the KanbanBOX App

- Touch display natively connected to the KanbanBOX App.

The logistics of the future

Make the management of logistic flows easier with wearable systems! They enhance the work of operators and increase the performance of repetitive actions, such as barcode readings.

- Acoustic feedback via a monotone sound

- Tactile feedback via vibrations

- Optical feedback via a 3-color status LED.

Case studies

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants and integrated KanbanBOX with SAP

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, and then integrated it with its own ERP, with the Oracle Sequencer and with the suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector

References