Level production with Heijunka and Sequencer

Two Tools to Tackle Fluctuating Demand

KanbanBOX is the right software for managing electronic kanban systems. With built-in Heijunka and Sequencer features, it helps you effectively address the challenges of unstable demand, improve productivity, and avoid the risks associated with overproduction.

With KanbanBOX’s Heijunka and Sequencer tools, you can:

-

Smooth out production fluctuations, eliminating the continuous cycle of peaks and downtimes caused by demand variability

-

Reduce shortages and inefficiencies resulting from irregular production activities, such as machine stoppages, supply delays, and wasted resources (raw materials, time, unsold finished goods)

-

Align production with actual customer needs, ensuring a steady workflow while avoiding overproduction and stockouts

The Benefits of Using KanbanBOX for Production Leveling

Regularity

Effectively mitigate the issues caused by inconsistent demand, which often leads to a disruptive cycle of high-stress periods followed by slowdowns in production.

Efficiency

By reducing production spikes and idle times, you also avoid related inefficiencies, like equipment downtime, early or late deliveries, supply chain disruptions, and wasted resources.

Visibility

Whether you manage one plant or multiple facilities, having full visibility into the production process is essential. KanbanBOX’s visual board gives you clear, complete control over every operation.

What Are Heijunka and Sequencer and How Do They Work?

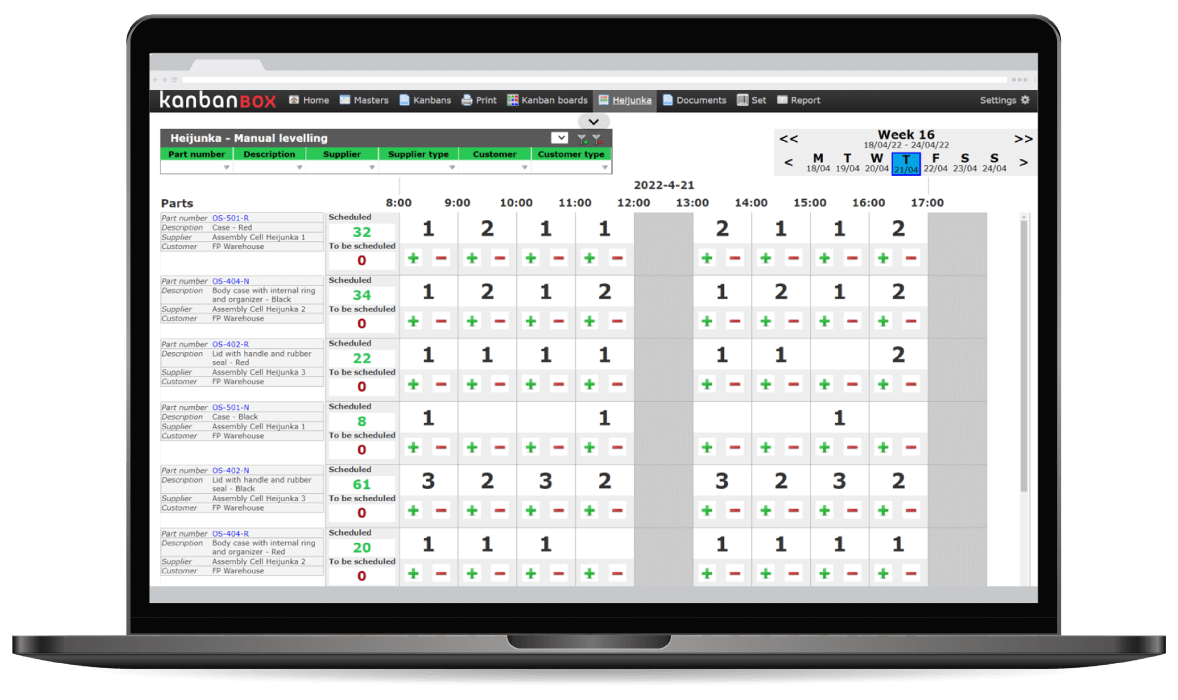

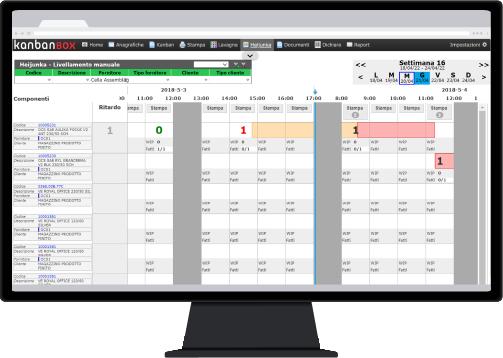

Heijunka: Stabilize the Production Rhythm

Heijunka is a Lean tool for production leveling that distributes workloads evenly across production cells, stabilizing both the pace of production and resource usage. It helps standardize component consumption and minimize supply fluctuations.

Key benefits of a Heijunka system:

- Leveling of production volume

- Leveling of product mix

- Elimination of consumption peaks

- Avoidance of inventory buildup

- Even distribution of labor, materials, and movements

Heijunka in KanbanBOX makes it easy to apply these principles in real production environments.

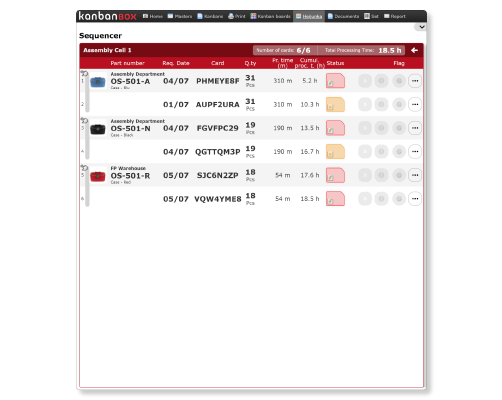

Sequencer: Distribute the Workload

The Sequencer is a production leveling tool that distributes the workload across production machines by determining the optimal production sequence.

This gives the production supervisor clear visibility into the full workload and enables effective distribution of tasks among available machines.

The Sequencer is the ideal solution in scenarios where production isn’t consistent and:

-

There is process variability

-

Resources are not always available

In such cases, a strict Heijunka approach may not be feasible, making the Sequencer the perfect alternative.

Learn how to level up your production with Heijunka

Heijunka is a Lean method for leveling production by distributing workloads evenly across production cells while minimizing supply fluctuations.

Read moreDefine the processing sequence with the Sequencer

The Sequencer is a Lean Manufacturing tool for scheduling the best sequence of operations on production machines or work unites, optimizing resources effectively

Discover moreSimplify Your Production Planning

With KanbanBOX, it’s easy to optimize production planning. The system allows operators at every station to keep working without interruptions, even in dynamic and variable production environments.

Watch the videoReferences

Case studies

Sacchi | Electrical Supply Distribution

Sacchi uses KanbanBOX to offer its customers a kanban-based sales service, ideal for recurring supplies and supports long-term customer loyalty

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, then integrated it with its own ERP, with Oracle Sequencer and with suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector