Why Choose Ekanban?

Why More Companies Are Adopting Electronic Kanban Systems

In today’s drive for operational excellence, “why choose ekanban” is a question many companies ask when looking to streamline their supply chain and improve efficiency, especially after seeing the benefits firsthand from partners or suppliers.

Ekanban (e-kanban or electronic kanban) stands out as a smart choice for businesses aiming to make their processes leaner, faster, and more connected. By digitizing and automating material flows, reducing waste, and enabling real-time visibility, ekanban empowers organizations to build smarter, more responsive operations.

Let’s explore the key reasons why more and more manufacturers are choosing ekanban.

Why Choose Ekanban: the advantages

Smarter, Easier Kanban Management

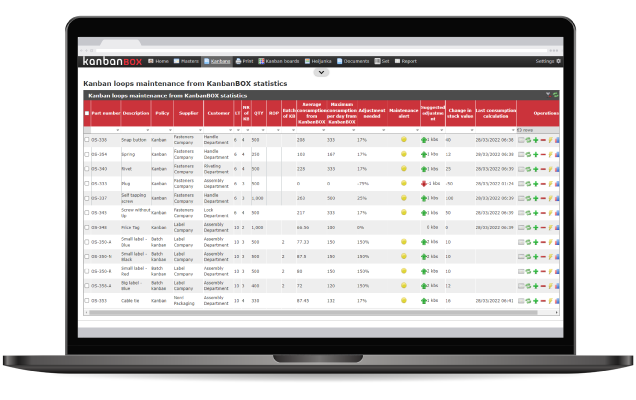

Ekanban systems collect real-time consumption data and automatically suggest optimal card sizing, dynamically adjusting to volume changes. This eliminates manual calculations, reduces errors, and makes the system easier to scale and maintain.

This was exactly the challenge solved by El.Co., as shared in this case study.

So one of the main answers to “Why choose ekanban?” is: because it enables fast and automated kanban maintenance, keeping your system lean and reliable.

Complete Process and Workflow Visibility

With ekanban, you gain instant access to critical metrics like consumption trends, replenishment times, and supplier performance. These insights help you detect bottlenecks, track performance, and support continuous improvement initiatives.

Every relevant action in the system generates automated, traceable alerts, keeping all stakeholders aligned and informed in real time.

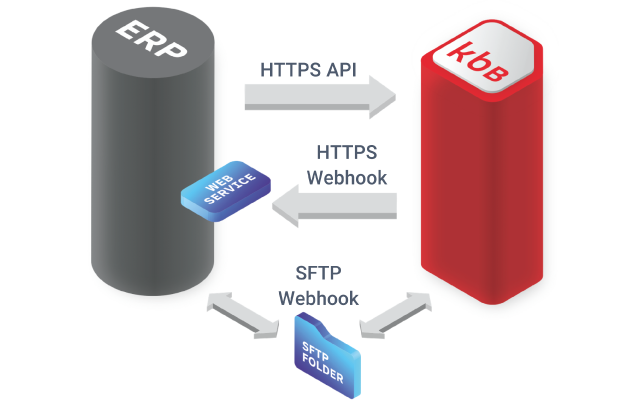

Full Integration with ERP, WMS, MES, and More

Ekanban integrates seamlessly with enterprise systems like ERP, WMS, MES, and beyond, building a connected ecosystem where every department works with synchronized data.

Rossi Spa achieved this transformation and shared their experience in this case study.

KanbanBOX is built for innovation and growth, ready to connect with RFID, automated warehouses, and other advanced technologies that evolve with your business.

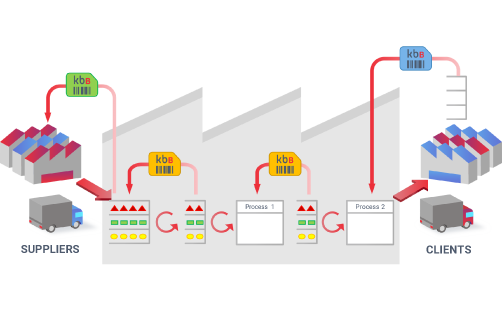

Coordination Across Multiprocess and Multisite Operations

KanbanBOX enables centralized management of complex flows across multiple processes or sites, even when distributed geographically. This ensures operational consistency and visibility across the entire value chain.

Whether you’re managing a single plant or a global network, ekanban creates transparency, alignment, and agility across all levels of your organization.

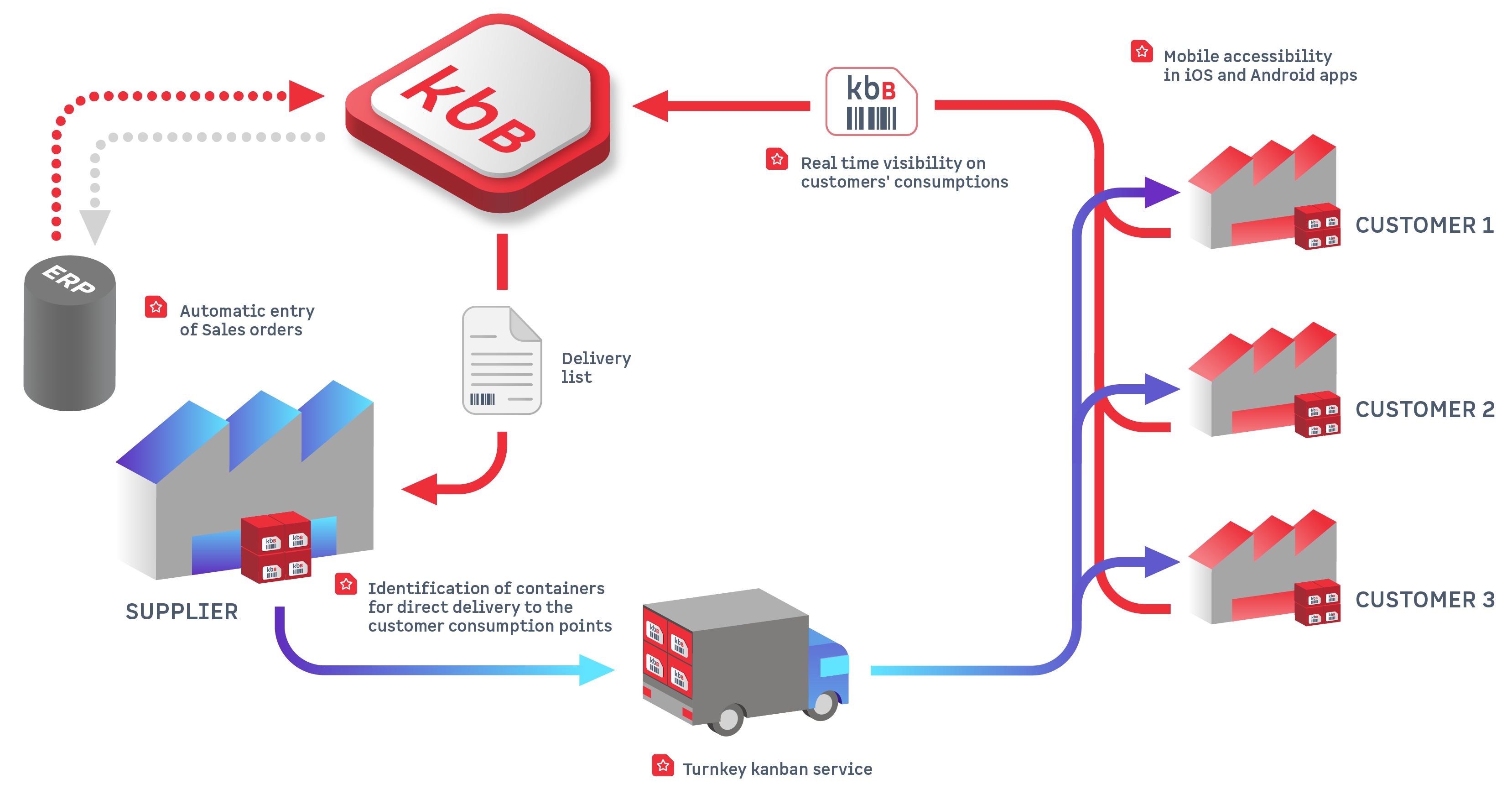

Real-Time Collaboration

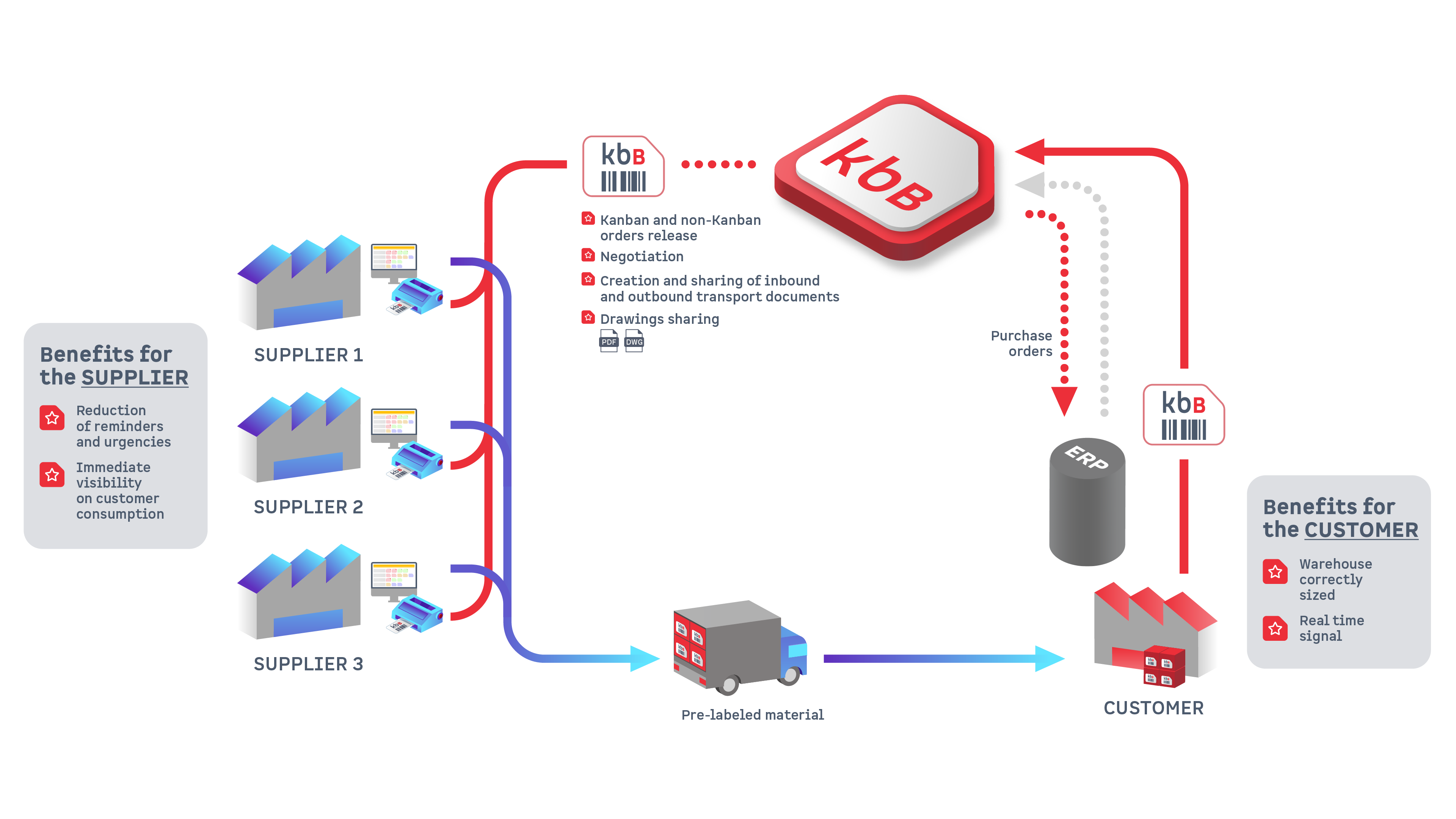

Ekanban with KanbanBOX goes beyond internal process improvement. It connects every supply chain partner (suppliers, subcontractors, customers) into your system with real-time access to consumption needs and replenishment orders.

The result:

- Fewer delays and errors

- Faster lead times

- More reliable deliveries

- A synchronized, collaborative, and proactive supply chain

Download the Free Ekanban Guide

Want to learn more about the benefits of electronic kanban?

Download our free guide and explore:

- What is an ekanban system

- Required technologies

- How it works (step-by-step)

- Key differences from traditional kanban

- Real-world benefits

- Data collection and process visibility

- Integration with ERP, RFID, WMS, and more

How Ekanban Works

Now that you understand why to choose ekanban, take a closer look at how the system works and how it helps customer-side processes trigger replenishment faster.

Explore how ekanban worksSimplify Kanban Card Printing

Tired of scattered Excel files and manual printing? With KanbanBOX, kanban cards are automatically generated, accessible in real time, and printable with one click.

Learn how to print ekanban cardsReferences

Some of our clients

Case studies

Sacchi | Electrical Supply Distribution

Sacchi uses KanbanBOX to offer its customers a kanban-based sales service, ideal for recurring supplies and supports long-term customer loyalty

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, then integrated it with its own ERP, with Oracle Sequencer and with suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector