The Warehouse of the Future is integrated with KanbanBOX

WMS, AGV, and automated warehouses in one connected and efficient system

KanbanBOX is designed to communicate seamlessly with the most advanced warehouse management technologies, ensuring digital continuity and scalability.

The system integrates with:

- WMS (Warehouse Management Systems), software dedicated to organizing and controlling warehouse operations.

- AGV (Automated Guided Vehicles), self-driving vehicles that transport materials without human intervention.

- Automated warehouses, storage systems equipped with robotic solutions for material storage and retrieval.

Thanks to these integrations, KanbanBOX meets the needs of companies that have already embraced the Smart Factory model, as well as those preparing for the future, adopting a flexible, scalable system designed to grow alongside their technological evolution.

Real-time visibility of material flows

Gain complete visibility over warehouse movements, allowing real-time monitoring of inventory levels and preventing delays or shortages along the logistics flow

Reduced storage and handling costs

Through automation and real-time control of logistics flows, KanbanBOX helps optimize stock management, effectively reducing waste and minimizing handling and storage costs

Optimization of production and distribution processes

By automating both material and information flows, KanbanBOX enables leaner and more efficient process management, improving operational performance at every level

The advantages of integration

The benefits of integrating Automatic Warehouse (WMS) systems, Warehouse Management software and driverless transport systems (AGV) with KanbanBOX are a real visibility on the physical flows of materials circulating in the warehouse and a reduction in costs associated with transport.

- Ease of access and stock management

- Correct data interchange

- Movement of goods to and from the warehouse in a lean and automatic way

- Correct compilation of picking lists based on recorded consumption

- Reduction of waste from a Lean perspective (delays or waits along the logistic flow, stocks of material and therefore of value trapped in the process, improvement of transport …)

- Optimisation of production, distribution and picking processes

- Enabling integration from a 4.0 perspective.

How integration between

KanbanBOX, AGV, and WMS works

By integrating existing AGV and WMS systems within the company with KanbanBOX, you can maximize the potential of all three systems, optimizing a wide range of processes from a Lean perspective.

Through this integration, KanbanBOX processes recorded consumption data and automatically generates material replenishment requests, sending the correct picking list to the WMS, without the need for manual input from operators.

The WMS then transmits the input to the AGV control software, which moves materials to the designated production, storage, or distribution areas.

This creates a fully automated and real-time synchronized material flow, reducing lead times, eliminating errors, and ensuring a continuous and efficient supply chain.

Thanks to the integration with KanbanBOX, warehouse management systems become Lean, delivering the right material, to the right place, to the right operator (human, autonomous vehicle, or robot), at the right time, and in the right quantity.

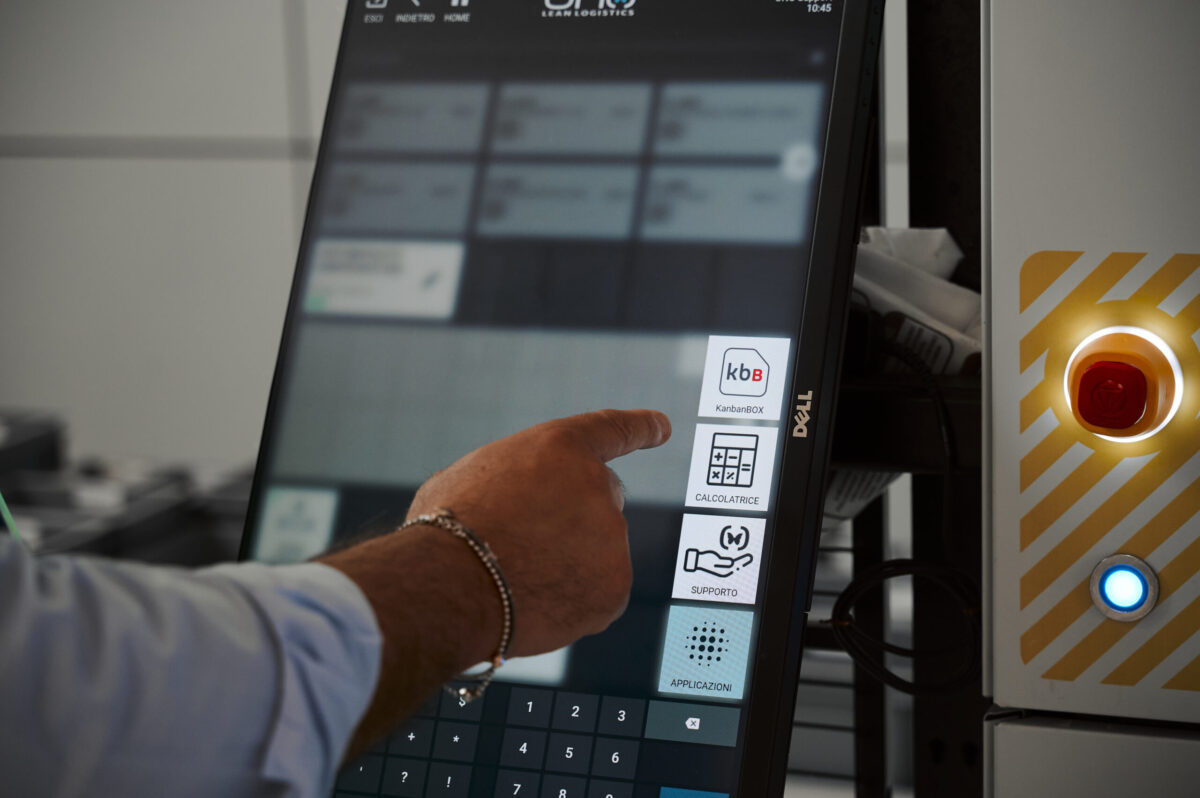

KanbanBOX and ONO Lean Logistics

Is your company interested in next-generation warehouse systems?

Since 2015, KanbanBOX has partnered with ONO Lean Logistics, a company specialized in automated warehouse solutions, to develop new functionalities and continuously enhance warehouse management through Kanban.

KanbanBOX and WMS

Based on recorded consumption data, KanbanBOX triggers material replenishment requests by communicating the correct picking list to the Warehouse Management System (WMS), without requiring manual operator input.

Not sure what a WMS is? Click the button below to learn more.

KanbanBOX and AGV

Based on the correct picking list generated in KanbanBOX, the input is transmitted to the AGV control software, which handles the movement of materials within production, storage, or distribution centers.

Not sure what an AGV is? Click below to find out.

Do you have any questions?

We are ready to give you all the answers

Case studies

Sacchi | Electrical Supply Distribution

Sacchi uses KanbanBOX to offer its customers a kanban-based sales service, ideal for recurring supplies and supports long-term customer loyalty

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, then integrated it with its own ERP, with Oracle Sequencer and with suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector

References