Ekanban: Benefits and Features

Lean Materials Management: Efficiency, Control, and Real-Time Visibility

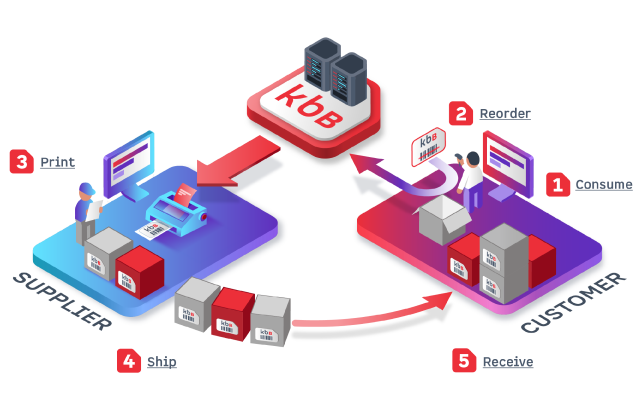

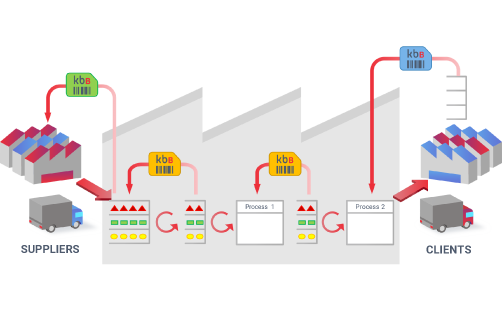

Ekanban, also referred to as electronic kanban or e-kanban, is the digital evolution of the traditional pull system. It preserves the core structure of classic kanban while overcoming its limitations through digital information flow, real-time data sharing, and process automation. This results in a more efficient, transparent, and responsive material management system, reducing waste, delays, and errors across the entire supply chain.

KanbanBOX is the ideal software to implement an ekanban system in a simple, scalable way, without disrupting your current processes. With an easily integrable platform, it supports companies of any size in digitizing their flows and boosting supply chain performance.

Move Beyond Traditional Kanban

- Eliminate the limitations of manual kanban

- Optimize your kanban system management

- Connect your entire supply chain, from customers to external suppliers

Apply ekanban where it matters most

Procurement

With ekanban, replenishment orders are automatically sent to external suppliers, reducing lead times and enabling a shared view of stock levels.

Production and Material Handling

Optimize internal logistics and production flows, even in multiprocess or multisite environments.

Sales and Distribution

Improve product availability and responsiveness to demand while reducing non-value-added tasks, inventory levels, and replenishment times.

What You Can Do with KanbanBOX’s Features

Optimize kanban system management

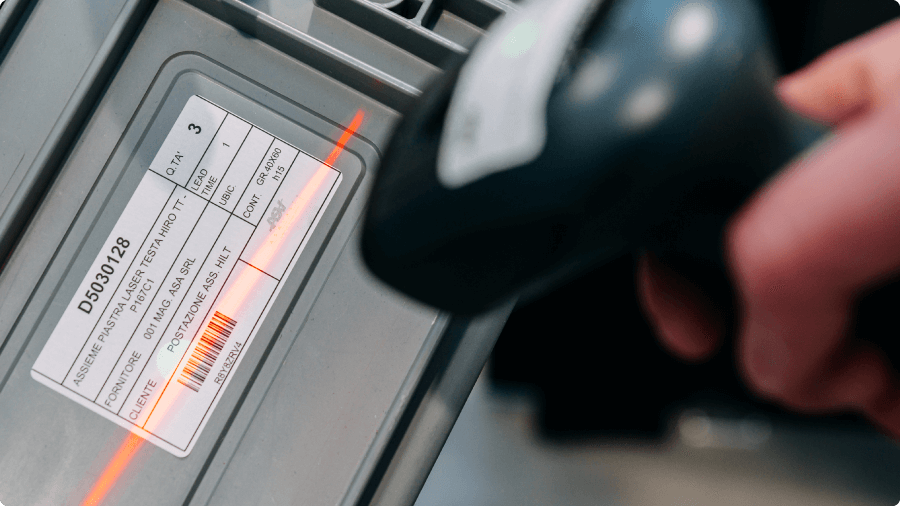

Simplify kanban system management, from printing cards to collecting key statistics, from sizing analysis to updating inventory levels. KanbanBOX gives you full control and keeps your system aligned with changing volumes and consumption mix, even for materials not traditionally managed with kanban. Everything happens quickly and in real time.

Go Beyond Company Boundaries with digitalization

With KanbanBOX, you can extend your digital kanban system to include both customers and external suppliers, turning collaboration into a true extension of your organization. The platform ensures full visibility, faster response times, and perfect flow synchronization for a leaner, more reliable, and agile supply chain.

Achieve deep integration with ERP, WMS, RFID, and more

KanbanBOX helps you reach the highest level of integration, connecting not only your customers and suppliers to your ekanban network but also your internal digital systems like ERP, WMS, RFID, MES, and others. The result: a fully connected ecosystem where materials and data flow smoothly, in sync, and without waste.

Download the Ekanban Guide

Get your free copy of our Ekanban Guide to learn everything you need to know:

- What an electronic kanban system is

- The technology you need to implement it

- How it works

- Key differences between traditional and electronic kanban

- Benefits

- Operational visibility and data collection

- Integration with ERP, RFID, WMS, and more

How Electronic Kanban Works

Electronic kanban is the modern evolution of traditional kanban, a system that helps companies produce only what is needed, exactly when it’s needed.

Learn how it worksWhy Companies Choose Ekanban

By adopting an ekanban system, you can reduce execution time by up to 80% thanks to cutting-edge technologies and real-time data insights.

Explore the benefitsSimplify Your Kanban System

Automated consumption data collection, optimal sizing suggestions, automatic kanban card generation… Everything you need to manage your system with maximum simplicity.

Read the case studyDiscover the full potential of electronic kanban

Case Studies

Sacchi | Electrical Supply Distribution

Sacchi uses KanbanBOX to offer its customers a kanban-based sales service, ideal for recurring supplies and supports long-term customer loyalty

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, then integrated it with its own ERP, with Oracle Sequencer and with suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector

References