Printing of kanban cards

Organise yourself from a Lean Visual Management point of view and try the power of a unique tool that is easy to customise

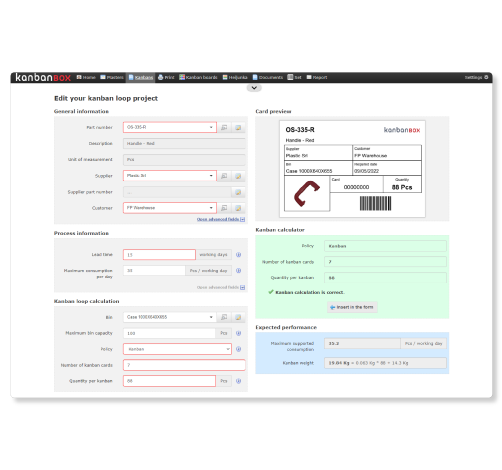

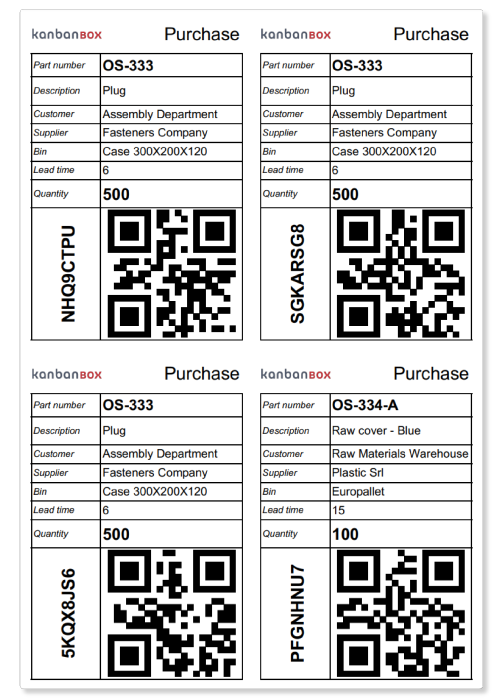

With KanbanBOX you can customise and print kanban cards with one click, to use them both in a traditional kanban system and with an electronic kanban. No more cards printed by Excel and information scattered in inaccessible files!

The KanbanBOX interface is designed to be simple, intuitive and understandable: no training courses are needed to successfully start managing the first kanban relationships!

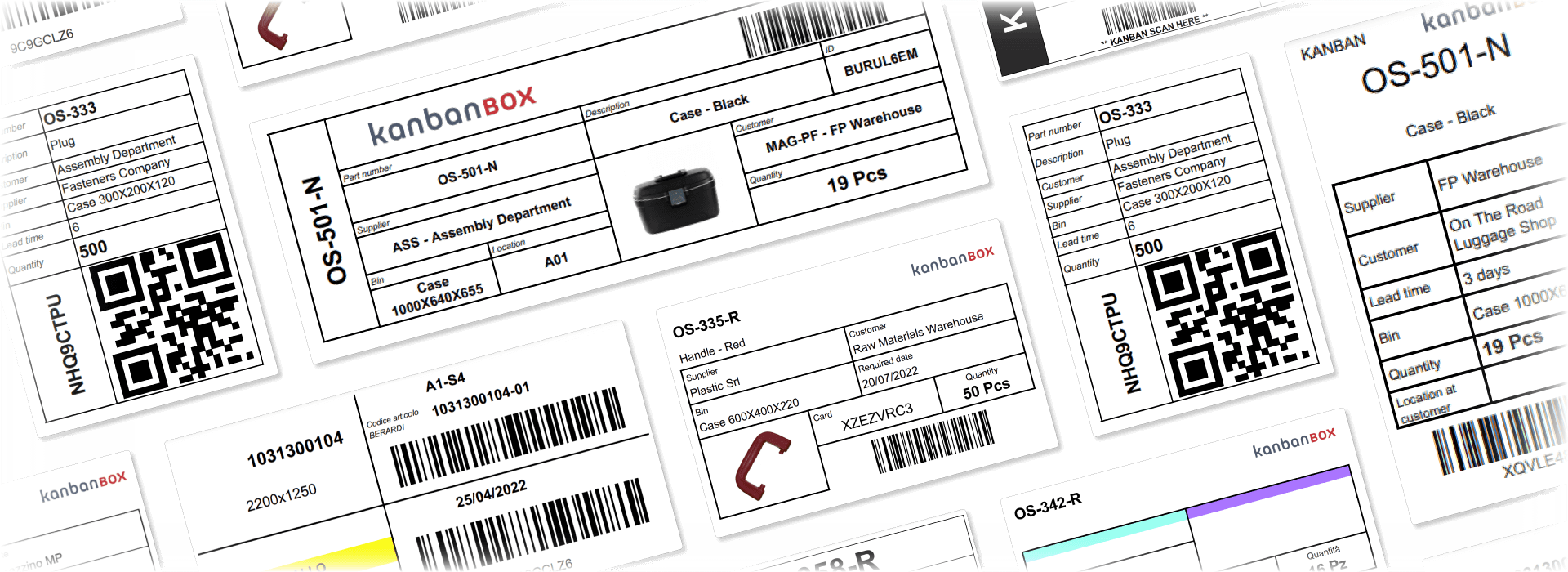

- print your cards from a visual perspective for clearer identification along your production processes

- choose from several ready-made and customisable templates

- automatically recalculate the correct number of kanbans and benefit from a variety of configurable statuses

Size the number of kanbans

and print them autonomously

KanbanBOX supports you in calculating the correct number of kanbans by carrying out the sizing according to:

- the maximum daily consumption in the period in question

- the Supplier Lead Time, the supplier’s replenishment time

- the safety lead time, the safety time

- the standard quantity of pieces in a container.

Automatically recalculate the kanbans

and choose from the configurable statuses

The kanban, with its identification card, serves as a purchase, production and transfer instruction, eliminating hard-copy orders.

In this way, the warehouse is under control, production is pulled and in line with orders and shipments:

-

create different templates for different kanban uses (e.g. production, purchase, sale or handling)

- select the print format and the information to be displayed, such as the company logo, component photos and colours for each department.

Find out about all the functionalities

for printing kanban cards

To meet different production needs, KanbanBOX provides:

- layout of customisable cards

- composition of several cards per page and double-sided printing

- addition of the image or drawing of the component, barcodes, datamatrix, QR Code.

Customise your cards or those of your customers

Customise your kanban cards by inserting:

- print format, company logo, component supplier and customer requesting it

- code and photo of the component, colour of the department

- time available for restoration and quantity to be restored.

How does the ekanban work?

A kanban is an information passing system that ensures that each operating station produces only what is required by the most downstream station.

Go to

Why choose

the ekanban

A kanban is an information passing system that ensures that each operating station produces only what is required by the most downstream station.

Go toCase studies

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants and integrated KanbanBOX with SAP

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, and then integrated it with its own ERP, with the Oracle Sequencer and with the suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector

References