KanbanBOX advanced features

KanbanBOX is more than just Electronic Kanban software: it’s a powerful platform packed with advanced features designed to streamline operations, enhance collaboration, and support lean transformation across the entire supply chain. Whether you’re managing production flows, working with suppliers, or integrating with your ERP, KanbanBOX gives you the tools to do more, all in one place.

Smart kanban management

Most customers choose KanbanBOX for its Electronic Kanban capabilities, and with good reason. One standout feature is Kanban Maintenance, a rare function in the industry that automatically suggests when to add or remove Kanban cards. This is based on real consumption, lead times, and usage trends, ensuring optimized replenishment and minimal manual effort.

Learn more about kanban maintenace reading El.Co.’s case study.

Make to Order product Management

With KanbanBOX, you can manage not only kanban orders but other types of orders like closed orders, all within a single platform. This centralization eliminates the need for disconnected systems, reduce complexity and gives you full visibility over every process and material in your supply chain.

Production Flow Management

Take your lean implementation further with built-in tools for managing complex production environments:

-

Multi‑Process: link multiple Kanban loops and synchronize replenishment across production stages. Read Mec – Track case study to Discover more.

-

Sequencer: sequence and balance tasks across machines or workstations in real time with a drag-and-drop board. See how it works.

-

Heijunka: level workloads and stabilize takt time by distributing order volume and mix over time. More details.

These features empower your team to plan, balance, and execute production efficiently.

Supplier Integration

KanbanBOX transforms supplier relationships into true collaborative partnerships:

-

Real-time visibility and Forecast sharing: suppliers and buyers share access to inventory levels, kanban cards’ statuses and sales forecasts to improve planning and reduce lead times. See KanbanBOX in action.

-

Centralized, transparent and fully traceable communication: exchange comments directly on Kanban cards, eliminating scattered emails and missed phone calls, bringing supplier collaboration to a higher level. Discover more.

-

Supplier negotiation: manage pricing, quantities, and terms directly through the platform, streamlining procurement processes. See how.

- Sharing forecast data: share forecast data with your suppliers, giving them the ability to confirm whether they can meet the expected production capacity. You can also optimize kanban sizing by taking seasonal fluctuations and demand forecasts into account. Learn more about the Forecast module.

Suppliers integration

Enable real-time collaboration and shared visibility across your entire extended supply chain: suppliers, customers and subcontractors.

Like Robopac, worldwide leader in packaging machine manufacturing that use KanbanBOX for supplier integration.

Read Robopac's case studyERP Integration

Seamlessly connect KanbanBOX with your company’s ERP to sync orders, inventory data, and master records.

Integration between KanbanBOX and your ERP system is not required for the platform. However, it can deliver significant benefits, as demonstrated by Gilbarco, leader in retail fueling products manufacturing

Read Gilbarco's case studyIndustry 4.0

Connect KanbanBOX with smart technologies like RFID, automated vehicles, and warehouse systems to digitize and automate your workflows.

A standout example is AGCO, a global leader in harvesting machinery, which installed two RFID portals to boost efficiency in Kanban card status updates.

Read AGCO's case studyBusiness Intelligence

With KanbanBOX, you can take advantage of advanced data analysis features that allow you to aggregate and interpret data to gain valuable insights into your processes.

This can be done in two ways:

- Directly within the platform, using Kanban Business Intelligence (KanbanBI), the native Business Intelligence module designed for real-time analysis of your kanban data. Discover Kanban Business Intelligence

- By integrating with external Business Intelligence tools, such as Power BI, if you want to aggregate data from multiple systems. Discover the Power BI integration

Functional tools

Increase the efficiency and effectiveness of your processes with dedicated tools:

- Workflow: set up automated actions, such as opening a dialog window when a kanban card is scanned to request additional information like an expiration date, location, or other details.

- Reports: access the complete history of all tracked information at any time, from kanban card traceability to comments, scans, and status changes.

- Documents: create, share, and archive incoming and outgoing documents linked to kanban cards or orders, ensuring everything is centralized, traceable, and ready for audits.

Optimize internal and external logistics

Streamline both internal and external logistics while maintaining full control over your stock levels:

- Milk-Run (internal & external): plan and manage cyclical collection and delivery routes inside your plant or with suppliers. Discover more.

- Inventory count: track, monitor, check your inventory in real time across different areas or locations to maintain lean, accurate inventory control. More details.

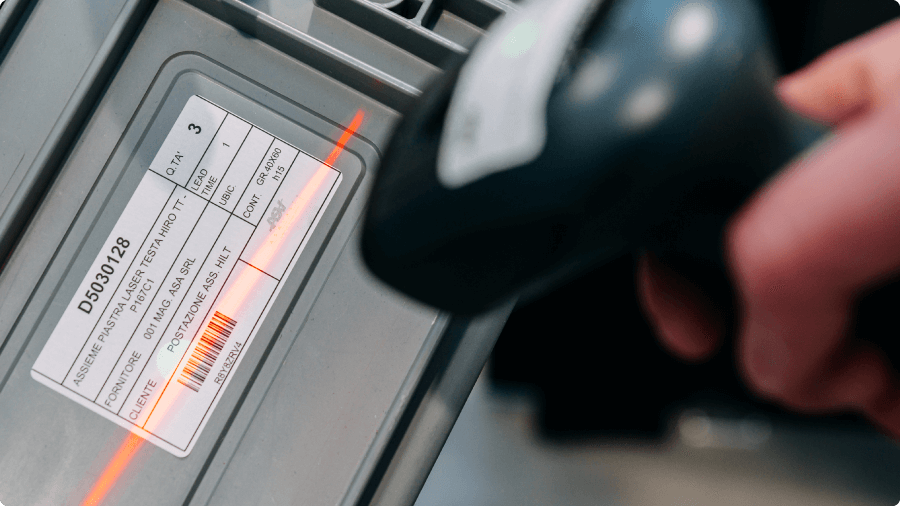

Efficient barcode scanning

KanbanBOX supports flexible and efficient barcode scanning to keep your material flows moving, no matter what device you use:

- Handheld terminals: integrate with industrial mobile devices for robust, high-frequency scanning in demanding environments. More details.

-

Wearable devices: free up hands and boost ergonomics with smart wearables that streamline operations. Find out more.

- KanbanBOX Mobile App: scan barcodes directly from the shop floor using the official app for quick, accurate kanban card updates. Download app.

References

Companies that use advanced features

Sacchi | Electrical Supply Distribution

Sacchi uses KanbanBOX to offer its customers a kanban-based sales service, ideal for recurring supplies and supports long-term customer loyalty

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, then integrated it with its own ERP, with Oracle Sequencer and with suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector